Design & Specification

Manufacture

Commissioning

Maintenance

Why would I require a Pump Station?

Pump Stations can be installed on sites for Foul, Storm & Grey Water for many reasons. The two most common reasons are…

- The drainage outfall is lower than the existing gravity.

- There is flow control required, for example:

Large storms draining off man-made surfaces could flood small rivers. To meet local authority discharge consents.

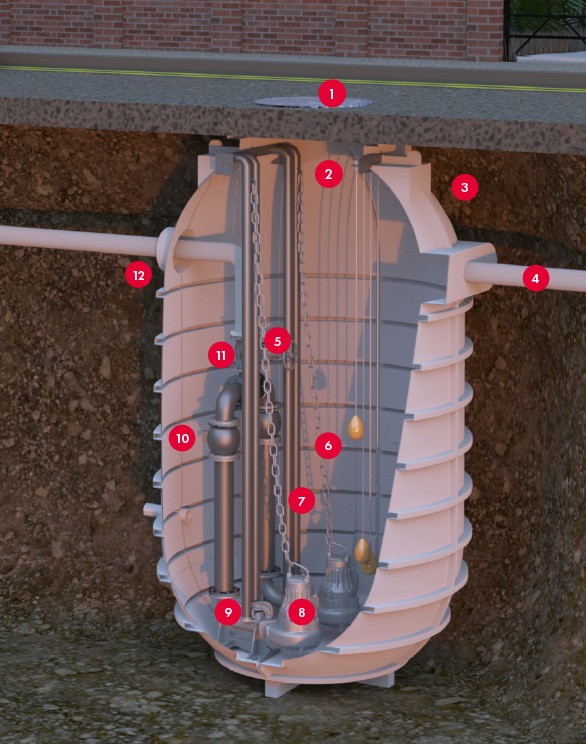

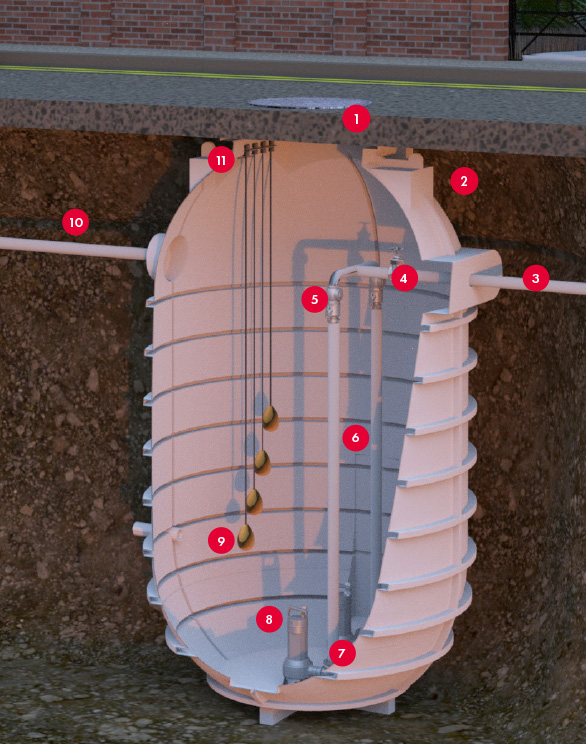

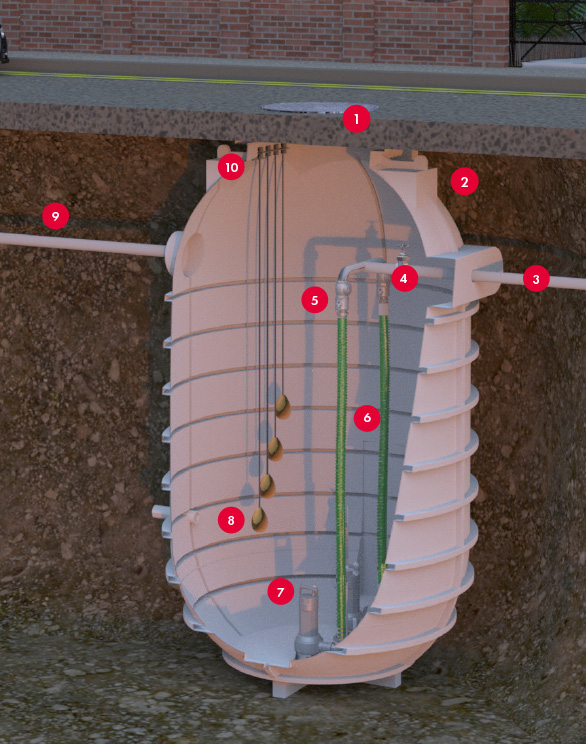

The Components and benefits Of a Pump Station

Explore the three main pump station types below...

which is the correct pump station type for me?

We have carefully selected a complete range of pump stations to ensure we can supply the right system to meet your needs.

Each system is available with a range of pumps and controls

The Above ground pump stations are also known as lift stations. Above ground pump stations are a compact package pump stations where digging... View the Range

Installation of pumping system to precast pump chamber, either to existing chambers or new. These chambers overcome site difficulties where ground... View the Range

We provide systems for the storage, attenuation, monitoring and treatment of surface water. Interceptors, or separators, provide an important role in the creation... View the Range

The V10 range of pump stations have been brought together by engineers who have owned, maintained, repaired, manufactured and designed pump stations. View the Range

The V18 range is a comprehensive selection of best-selling packaged pump stations for foul and surface water pump systems. The range is based on 3... View the Range

The V25/V30 range is a complete selection of large GRP packaged pump stations for foul and surface water pump systems. The high-quality tanks... View the Range

the order process

- Design and submit proposal to client

- Order is placed to Dura Pump

- Drawings are issued to client

- The client approves the drawings

- Pump Station goes to be manufactured

- Delivery is scheduled with client

- Client offloads and installs tank

- Pre-commission form signed by the client

- Dura Pump arranges commission

- Servicing/maintenance plan proposed to client