The Challenge

At Dura Pump, we can provide bespoke systems to meet customers’ challenging requirements. For this project, we were approached by a factory that produced plastic road barriers. To boost their business, they wanted a solution that would improve the sustainability and productivity of their production line.

Part of their quality procedure involved filling barriers with water to check for leaks (before dispatch). To improve efficiency and reliability, they needed a system that would fill and empty road barriers automatically without breaking any seals or removing any bungs from the newly moulded barriers. Previously, this was a process taken on by the workers and it was highly labour intensive.

In addition, there was the opportunity to minimise or zero the amount of labour that was required for filling and emptying the barriers. This process would have originally also needed personnel to carry out the job, making labour hours and costs a significant factor.

Our Solution

Following an assessment of the factory’s demands and listening to the requirements of the client, our team evaluated various options and designed a semi-automatic system to meet their needs.

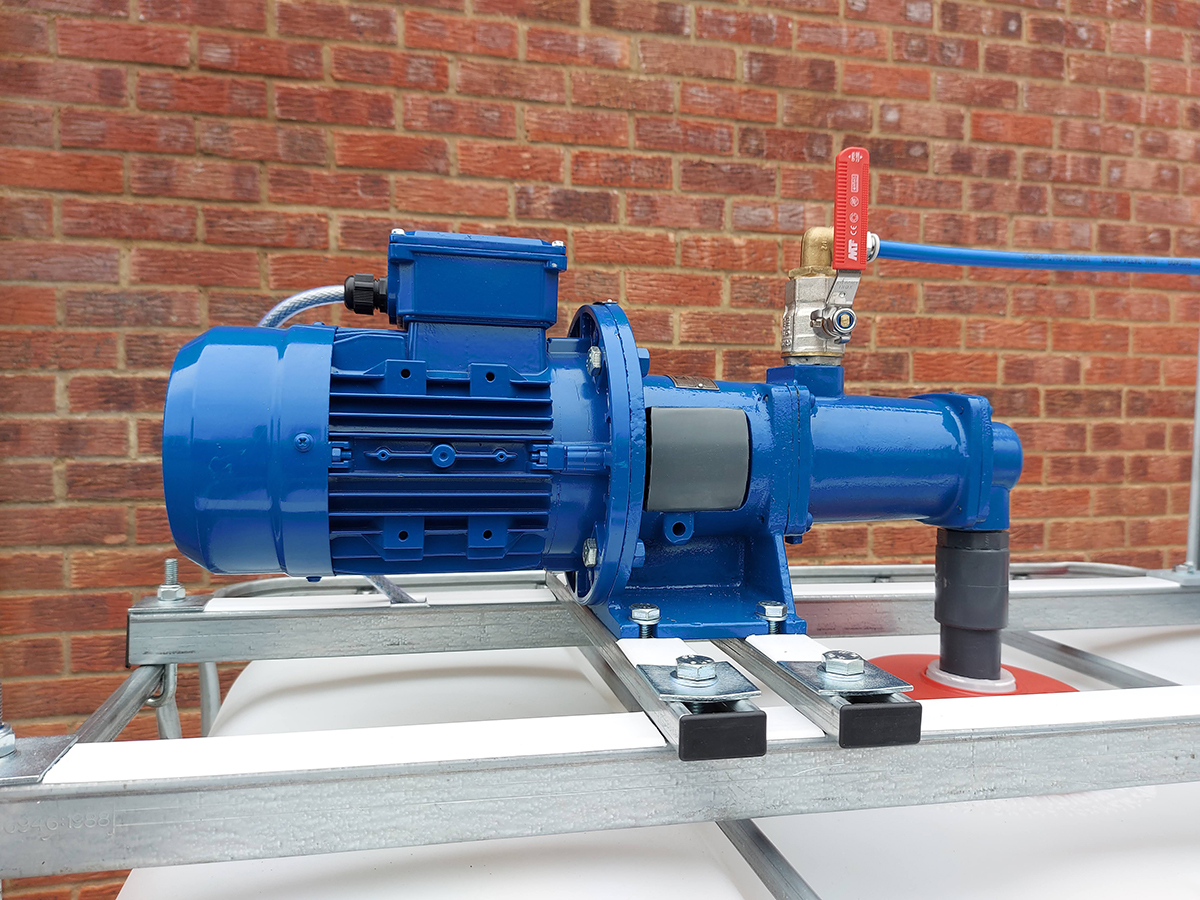

A progressive cavity pump – mounted to a 1000-litre water storage tank – that could work both ways enabled us to fill and empty the barrier by working in reverse. The storage tank provided sufficient water capacity for this operation to be performed as and when the factory needed it.

One of the main requirements from the customer was that it should work automatically. This would allow the operator to simply switch the system on and walk away, and the pump would automatically stop when the barrier was either full or empty.

The system was built on a skid and could be moved around as one. The advantages of this are that systems are easier to manoeuvre, the whole system can be tested off site, and it’s also easier to connect to the existing pipework.

The Results

Reduced labour costs and increased operation quality have resulted in greater customer satisfaction! Having this barrier testing system in place guarantees that the factory’s quality checks are carried out more efficiently without the need to remove any parts manually from the new barriers. The supplied semi-automatic system has fulfilled the customer’s requirements and saved them labour hours while reducing the running costs of their production process – fantastic advantages for a busy business.

Another true package system completed by the Dura Pump team, living up to our mission of being “the fluid control specialist that guarantees increased productivity and profitability for our clients through reliable and efficient solutions.”

Related Case Studies