The Challenge

A control system at a busy food factory had become obsolete and failed, and the Dura Pump engineers were challenged with replacing it. In normal circumstances, this would be a straightforward job. However, the production line at the site relies on functioning pumps to operate so we had to carry out the job with minimal downtime and disruption.

Our Solution

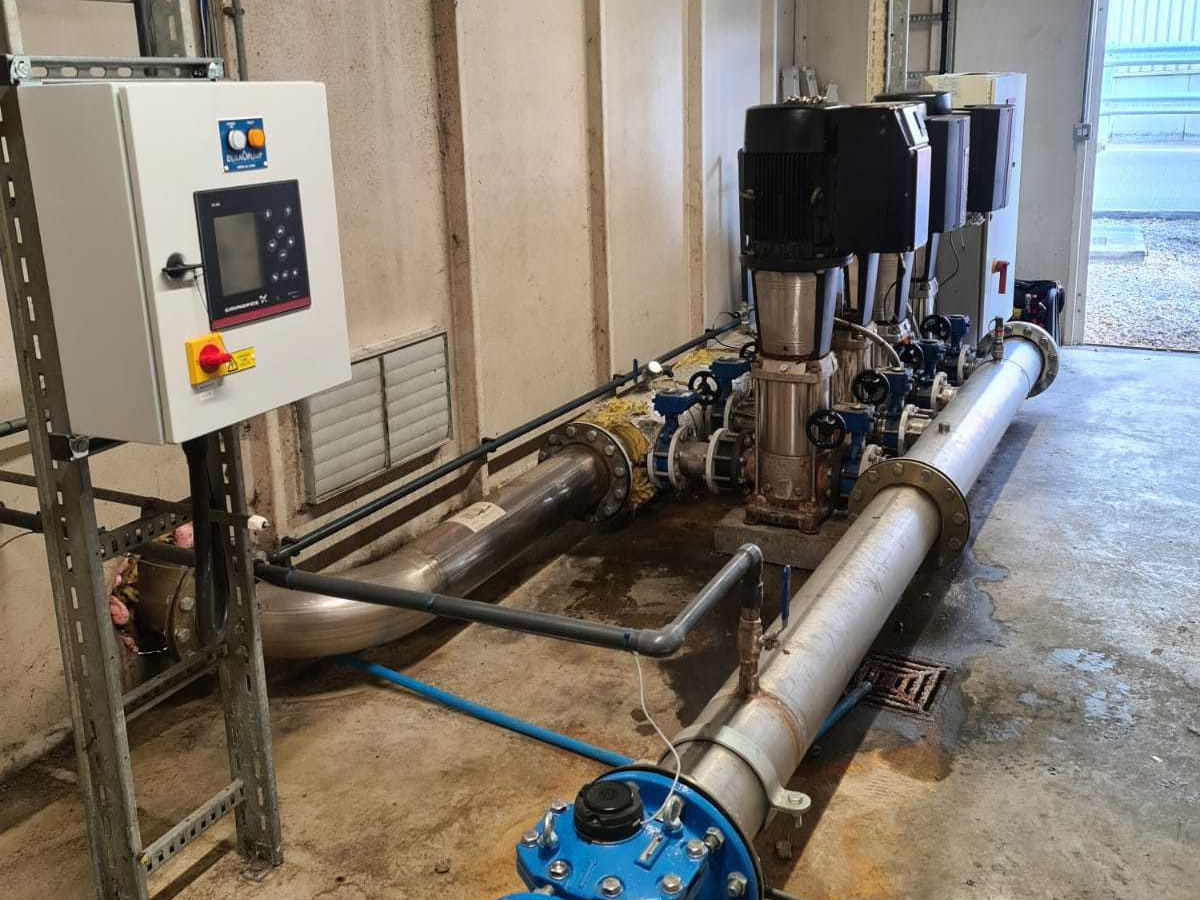

We constructed the control panel off-site, installing the Grundfos CU 352 onto a stand that would sit next to the booster sets. We fitted new cables to all pumps to ensure there would be no fault when the new control panel was fitted.

On arrival at the site, the new panel was simply mounted and the power supply switched across from the old control panel to the new panel. This meant there was only 20 minutes of downtime on the production line.

The Results

Our engineers reduced the overall time spent replacing the control panel to 20 minutes, saving the production line from hours of disruption. This helped keep the company running and had minimal impact on the efficiency of their process while giving them a solution that would boost their capability in the future. The new control panel is now fully functional and providing 100% reliability.

Related Case Studies