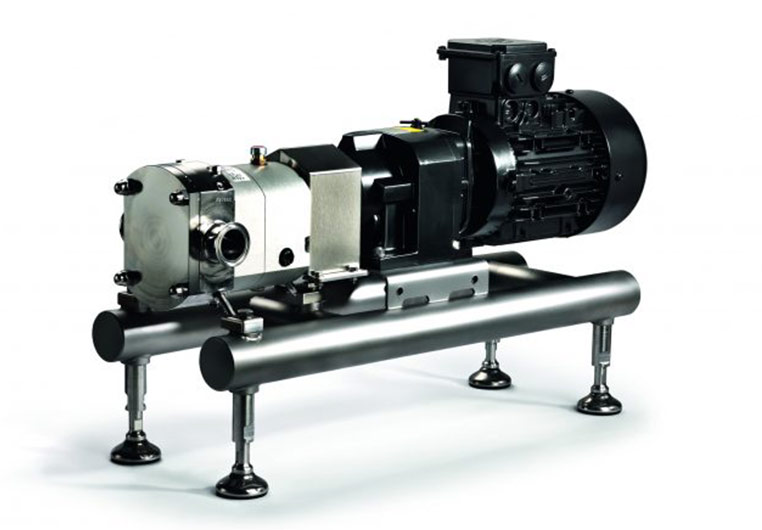

Barrel pumps are a positive displacement piston pump that traditionally uses compressed air as its power source, however these pumps are also available as an electric operated unit. As the air piston moves upward, the pump piston also moves upward, causing the barrel chamber under the pump piston to fill with fluid. When the air piston makes a downstroke, the pump piston also makes a downstroke, transferring the production fluid in the pump barrel to your required point of discharge.

These barrel pumps are also available as Drum and bin unloaders to evacuate viscous materials out of containers, such as IBC units. This process is highly efficient and allows a fast change of containers. This results in a minimized downtime on your production time. While being able to empty up to 99% of the material from the container, they have a one size follower plate and seal to accommodate straight-sided and tapered drums.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800