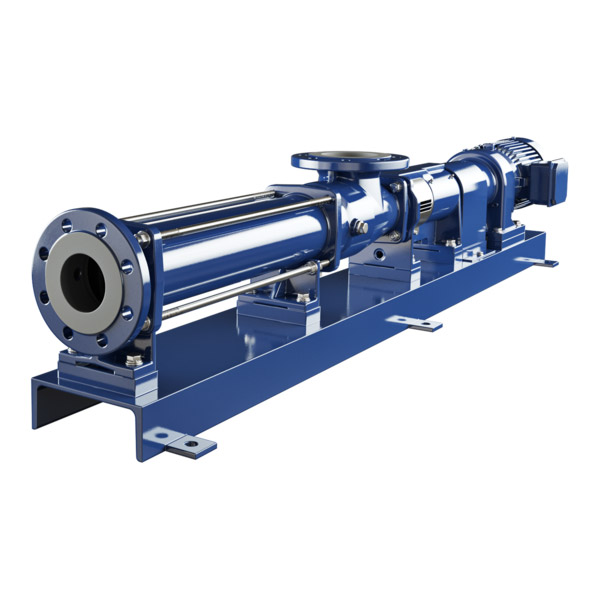

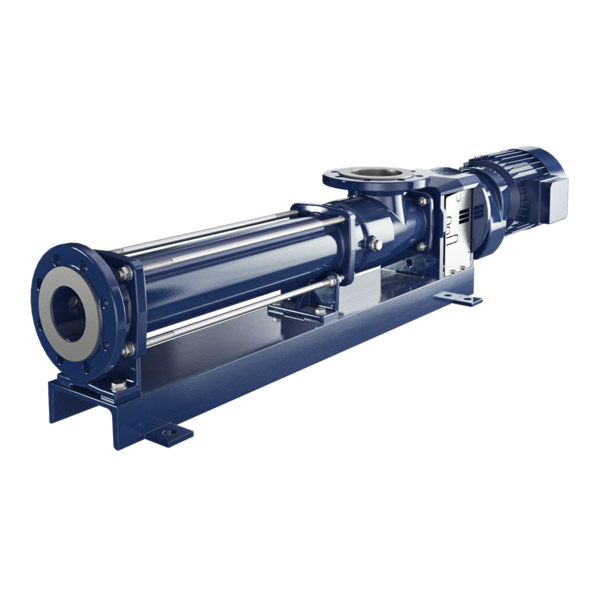

These Progressive Cavity Pumps are equiped with smart maintenannce solutions, and are easy to maintain in place. These pumps can be used in most industries or sectors pumping low-viscous media with or without solids.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800