Why Am I Experiencing Persistent Issues With My Pump?

Posted on 20th May, 2022 by Ozz

Posted on 20th May, 2022 by Ozz

There are some common issues that will cause regular or often pump failure. These include:

- Mechanical seal failure

- Bearing failure

- Corrosion

- Motor failure

- Cavitation

Why is my mechanical seal failing?

Mechanical seals prevent pumps from leaking by containing the pressure of the pumping process and withstanding friction caused by the pump shaft rotating. A functional mechanical seal should result in reduced wastage and a more efficient, cost-effective pump system.

But it’s important to know that mechanical seals are the most common cause of pump downtime. In fact, they account for more pump repair costs than any other part of a pump. Therefore, it’s critical to install and maintain mechanical seals properly to prevent dreaded costly failures.

Seal failure is often caused from the following, so keep an eye out for:

- System running dry

- Air locks

- Incorrect specification

- Incompatible materials with the fluid being pumped

- Change of operating parameters

- Cavitation

- Incorrect installation

- Pump misalignment

What’s causing my bearing to fail?

Pump and motor bearings should last for years, so if failures are becoming a regular occurrence, we’d recommend checking:

- Pump alignment (long coupled pumps)

- Quality of bearings installed

- Lack of lubrication

- Bearing housing wear

- Shaft wear

- Cavitation

- Incorrect installation

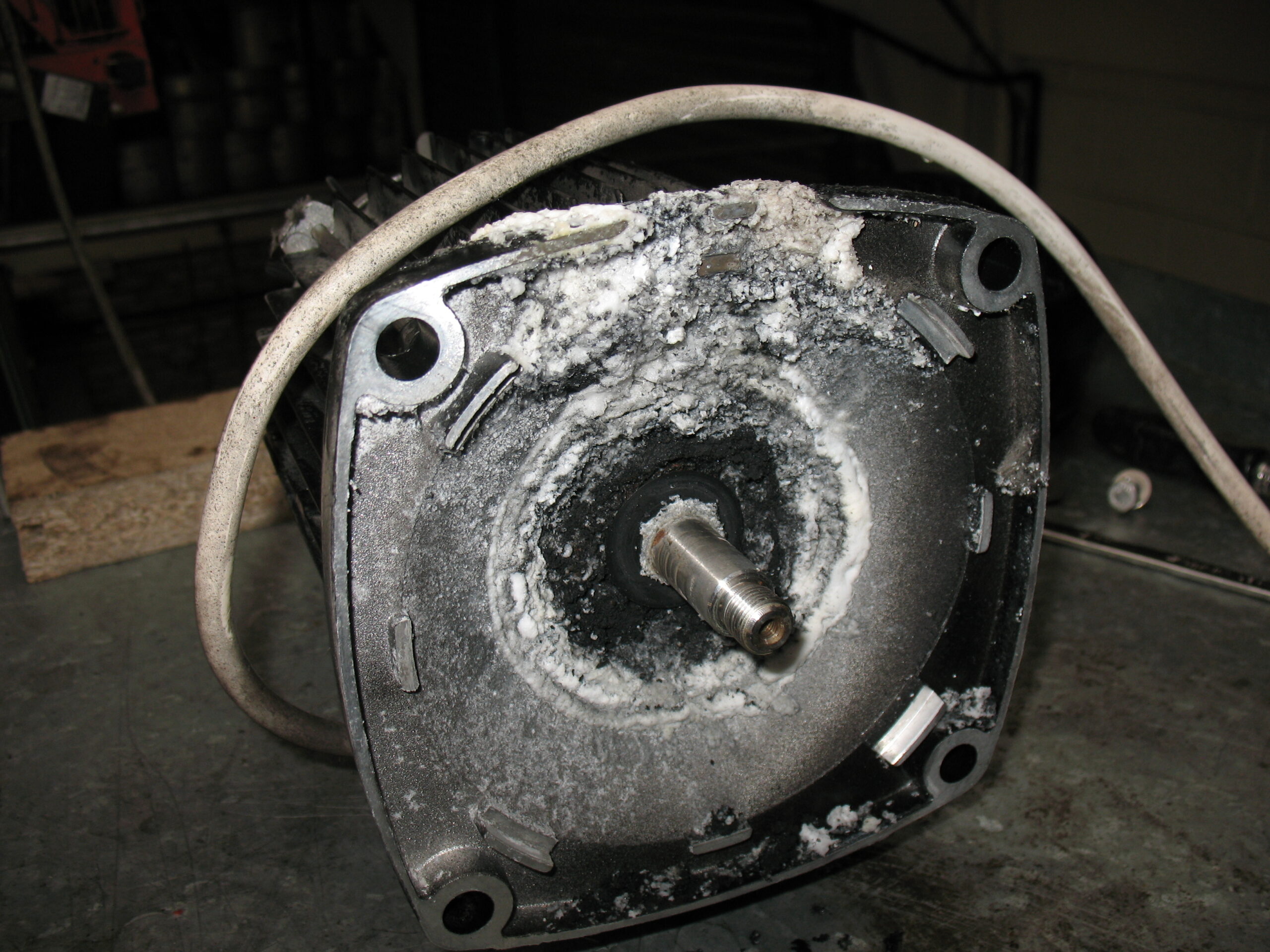

What is causing corrosion on my pump?

Corrosion of the pump housing, impeller or other parts on the pump are normally caused by two factors. The most common factor is the liquid being pumped is not compatible with the materials of the pump. For example, a cast iron pump being used to pump an acidic liquid. The second factor is cavitation. Damages or failures within the pump might first appear to be corrosion, but they are actually caused by cavitation within the pump.

It’s good to be aware that chilled water pumps often corrode externally due to condensation build up, but rest assured that normally this won’t affect the pump as it is only external.

Why is my motor failing?

Motors fail for a number of reasons, but in many cases motor failure is caused by an external factor such as pump mechanical seal or bearings failure.

If a mechanical seal is leaking, it will cause water ingress into the motor causing the motor to trip out due to low insulation. This can also lead to the bearings seizing up.

Bearing failure can cause an excessive load on the motor, which in turn creates excess heat. If the motor is not correctly protected via thermal overloads and thermistors, this will eventually cause the motor to burn out.

Other factors that can lead to motor failure are:

- Incorrect power supply, e.g. phase lose

- Regular stopping and starting

- Incorrect electrical installation

- Controls fault

- Incorrect pump specification (running off curve)

What is pump cavitation?

Cavitation occurs when air bubbles are generated inside a pump because there is insufficient water available to meet the flow requirements of the system.

Internal pressure changes in the pump cause the pump to suck the air out of the water, leading the air bubbles to implode. This process erodes the impeller surface, as well as the seal and bearings. If left untreated, the surface of the impeller will suffer a great deal of damage and will become scratched and eaten away at.

Pump cavitation occurs in two types (suction and discharge) and can be caused by clogged filters, blockages, poor piping design and improper specification of pumps.

If you’re experiencing cavitation within your pump, the first sign will be leaking from the mechanical seal. The front bearing may also seize. The sound of pump cavitation will also be very distinct and excessive.

Eliminate pump failure with Dura Pump

Pumps are built to last and normally fail due to inaccurate specification and installation. If you’re experiencing regular issues and always needing to replace or repair a pump, we recommend a full pump troubleshooting and fault-finding investigation to ensure you get to the root cause of the failure. This will save you splashing out on regular costly repairs and result in long-term savings. Get in touch with the Dura Pump team to start saving today.