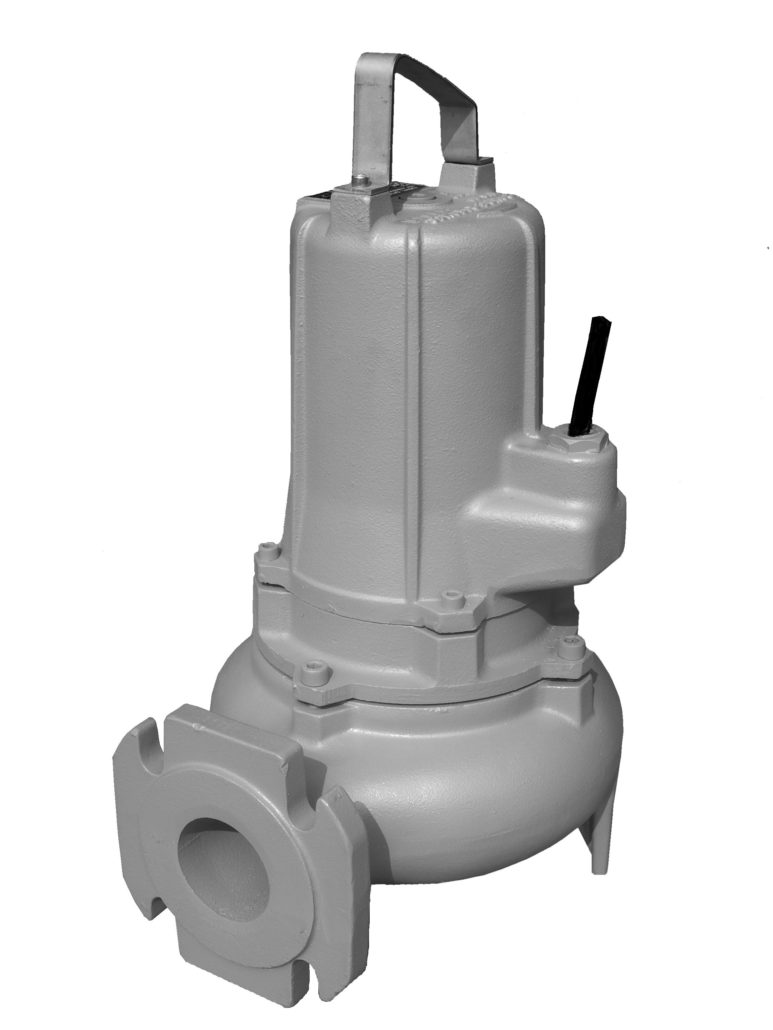

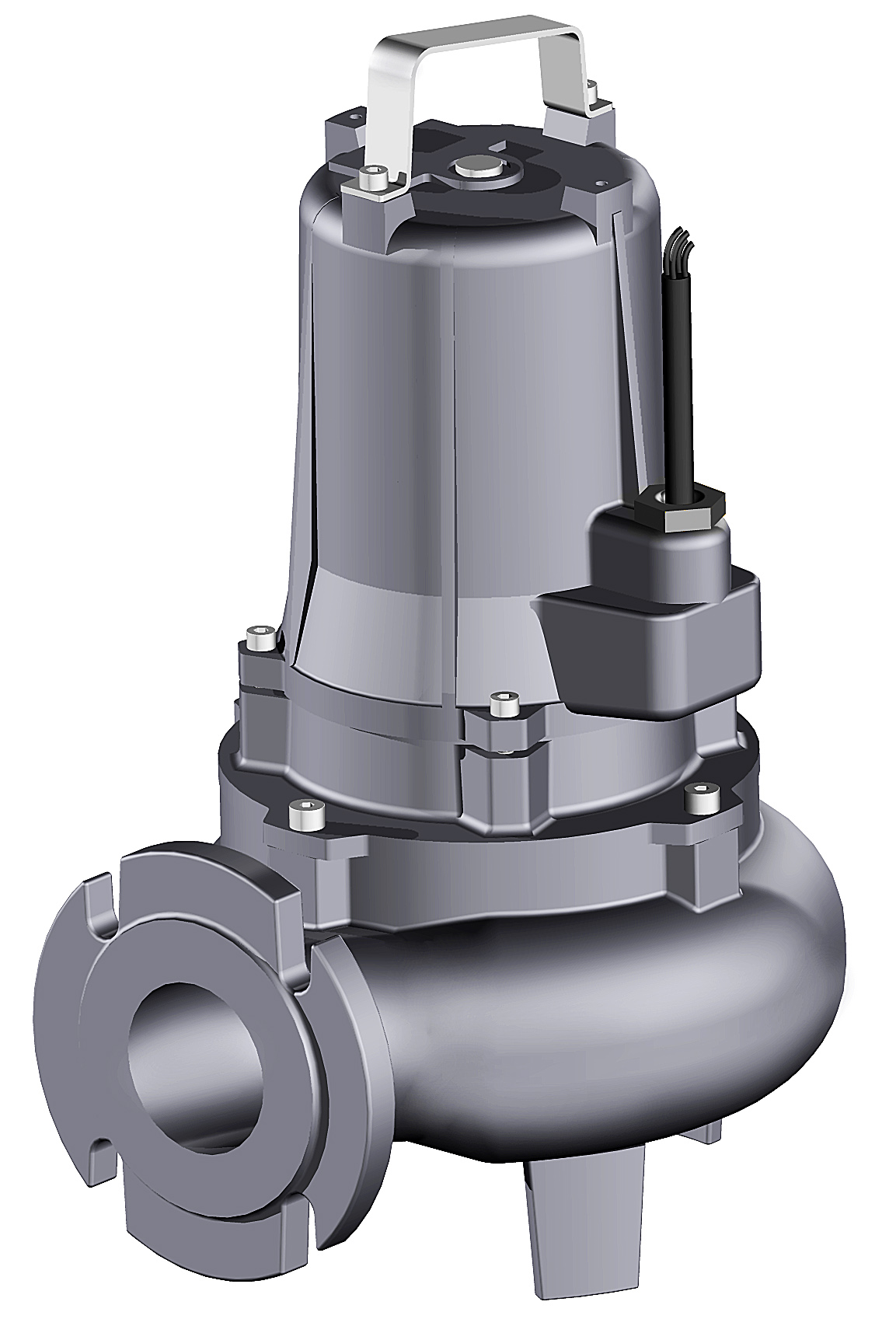

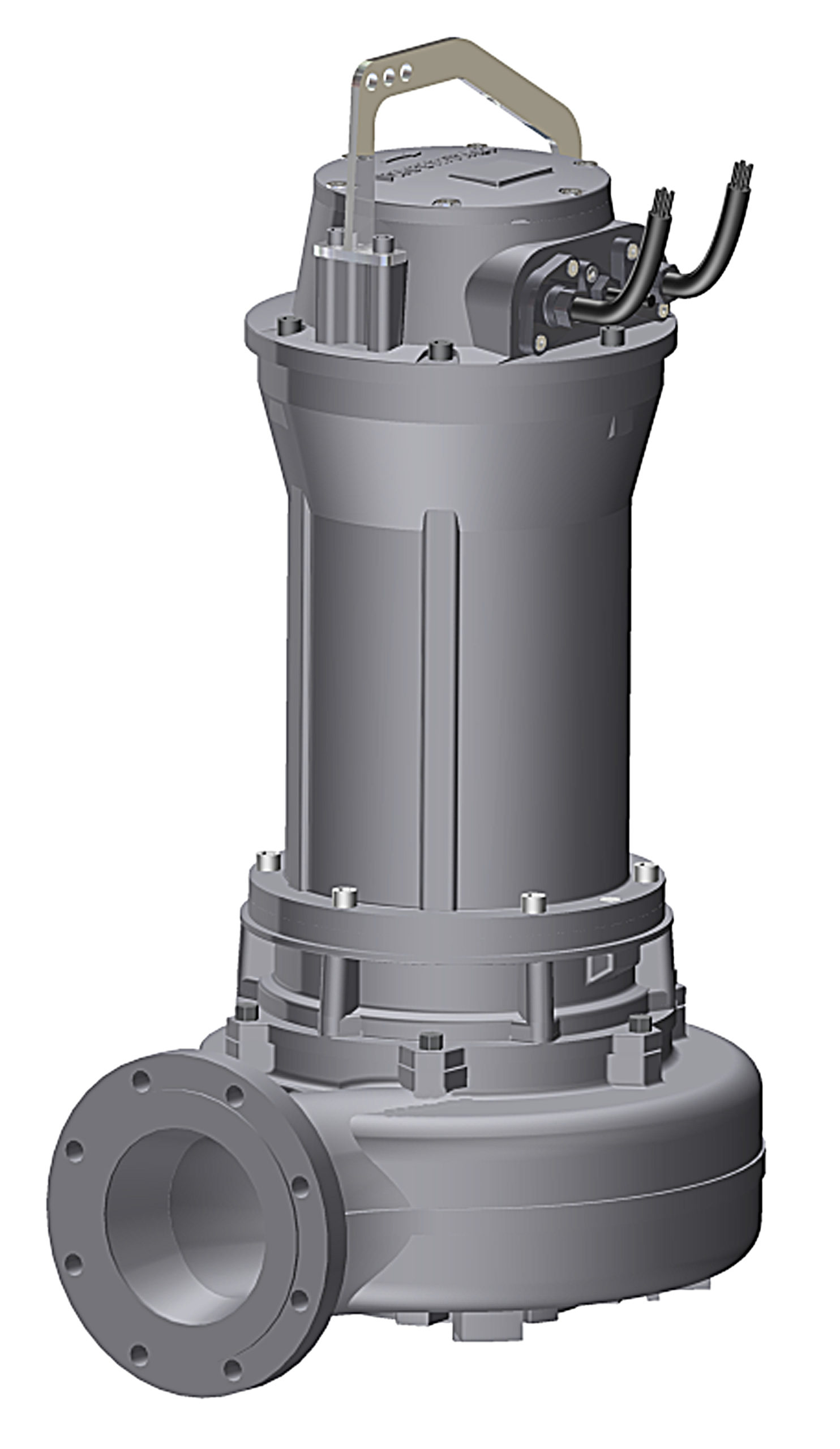

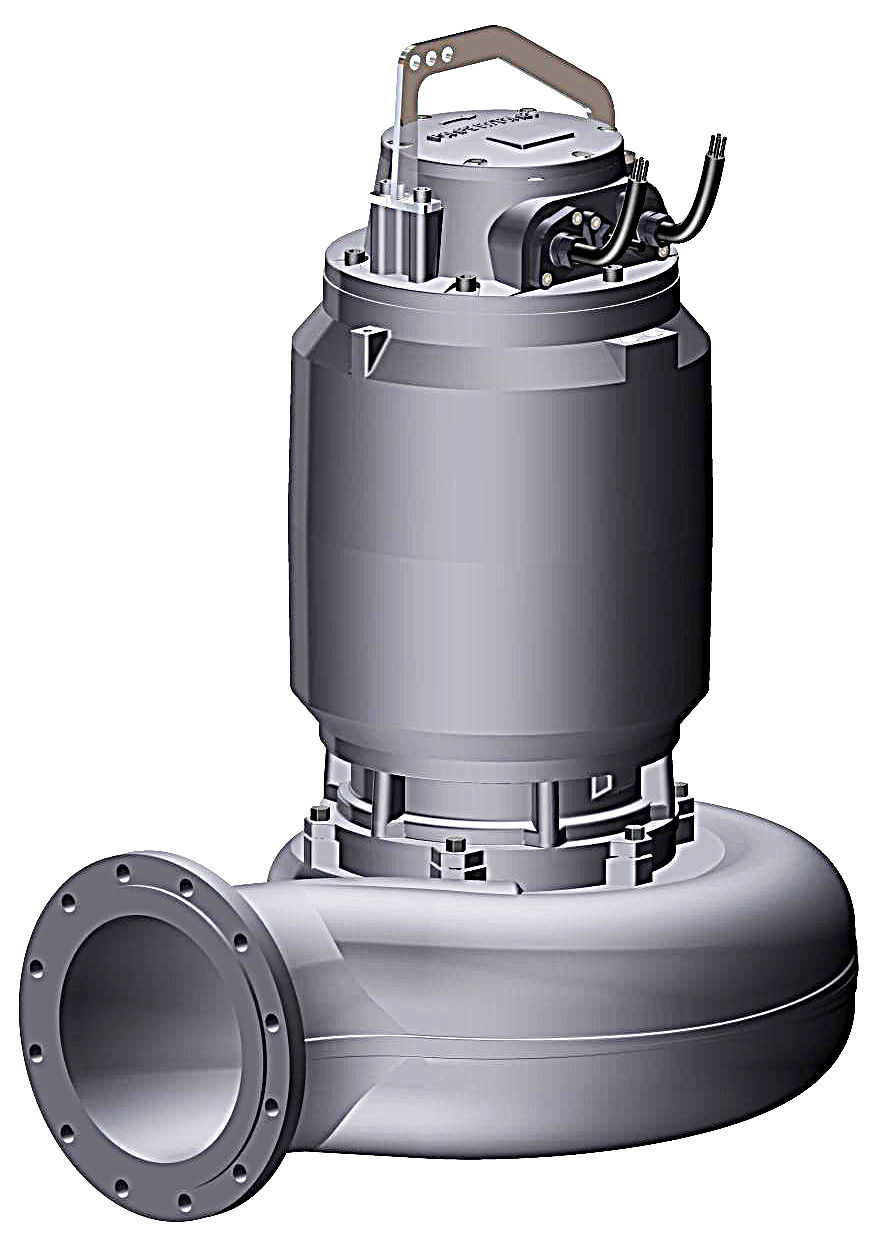

A sump pump is a small submersible pump that is most commonly installed in the lowest part of premises such as a basement, cellar or plant room. The role of the sump pump system is to keep the area under the building dry or to prevent flooding.

Sump pumps work in conjunction with a sump pit or sump pump tank. This pit is built beneath the level that needs to remain dry, which is usually the floor level. Water or other waste liquids that may spill during a process will collect in the pit as it is channelled there and be pumped away to prevent flooding.

Options of low suction pumps, more commonly known as “puddle suckers”, for emptying shallow pits or spillages.

Small sump pumps are often very critical in many applications. A failed sump pump could mean a flooded factory floor, a flooded store or a flooded plant room. Often they are overlooked. However they are typically a cheap and quick install, that can save thousands.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800