How much does it cost to run different sized pumps?

Different types and sizes of pumps will have different sized motors, which will affect how much they cost to run.

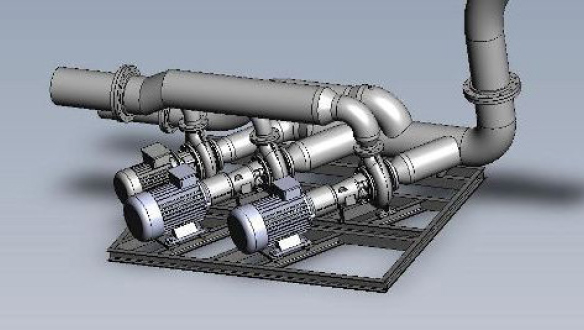

Design & Specification

Manufacture

Commissioning

Maintenance

We have categorised our system building into 3 key areas...

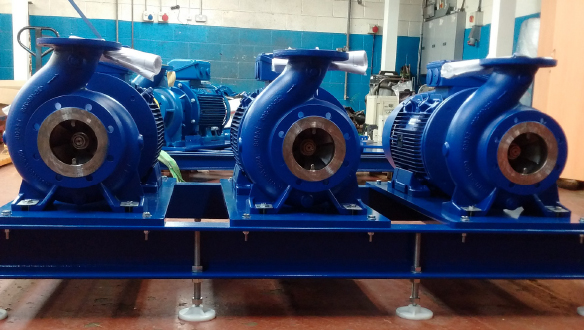

Our systems can be supplied ready to plug-in and go on site, pre-tested and commissioned in our workshop. Our supplied package systems can include:

Typical applications: Hygienic systems, washdown systems, test rigs, seal flush systems, wastewater systems.

We enjoy providing solutions for even the smallest applications, send us your challenge and our team will provide you with a reliable and efficient solution.

Our systems can be delivered to the site, pre-tested and ready to install. Once the installation is complete, our team of expert engineers will attend the site and commission your system. This ensures you are covered by our guarantee.

Our package systems can include:

Typical applications: Hygienic systems, washdown systems, test rigs, waste systems, fill and spill systems, booster sets, chilled water systems, environmental protection systems – oil detecting, manufacturing process systems.

We enjoy providing solutions – give us your challenge and our team will provide you with a reliable and efficient solution.

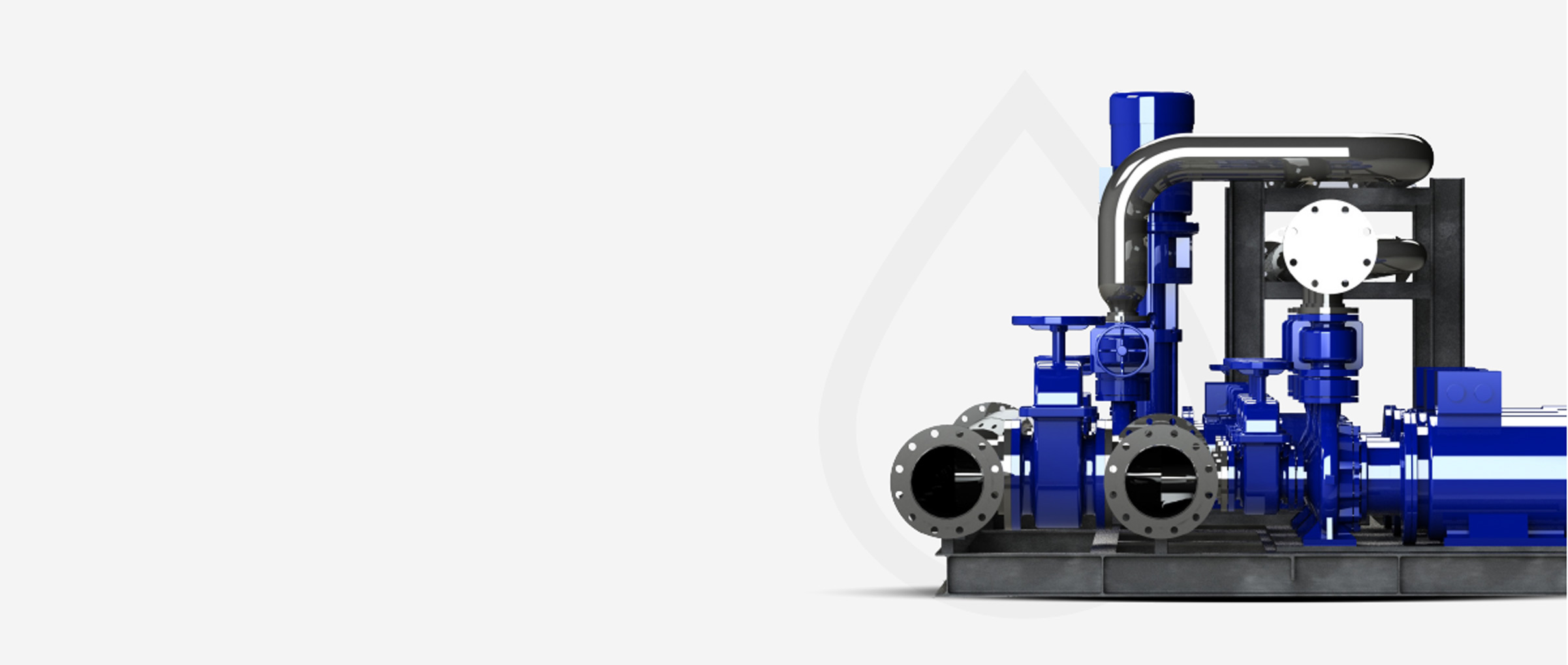

Our systems can be delivered to the site, skid-mounted, pre-tested and ready to install and commission by our team of engineers.

Our team will design and install your system to ensure minimum downtime. Using off-site manufacture and fabrication of systems, typically skid mounted and a close working relationship to understand your process, we can use features and methods that ensure minimal disruption and a seamless switchover.

Our package systems can include:

Typical applications: Chilled water systems – lift, delivery and quench, test rigs, wastewater systems, fill and spill systems, booster sets, energy-saving projects, process systems.

We enjoy providing solutions – give us your challenge and our team will provide you with a reliable and efficient solution.