The Challenge

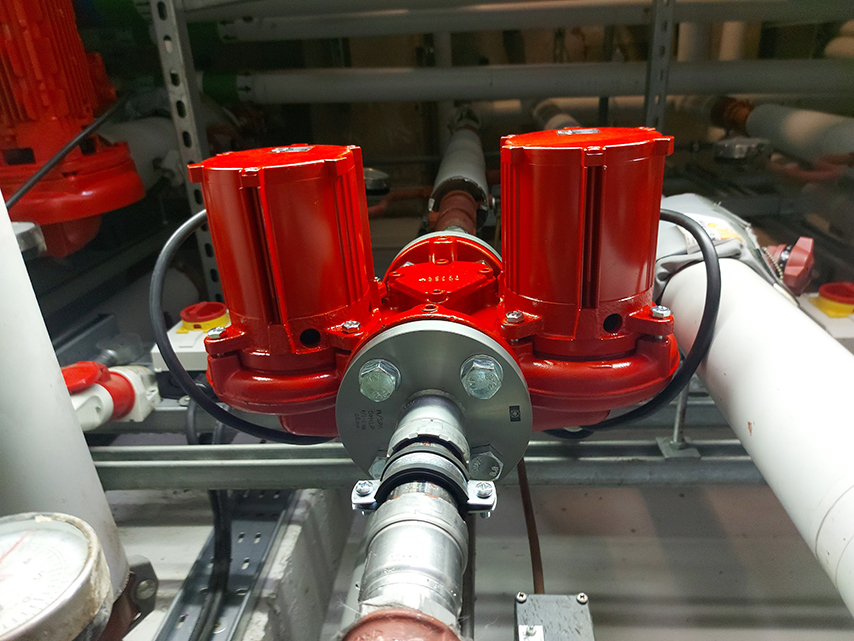

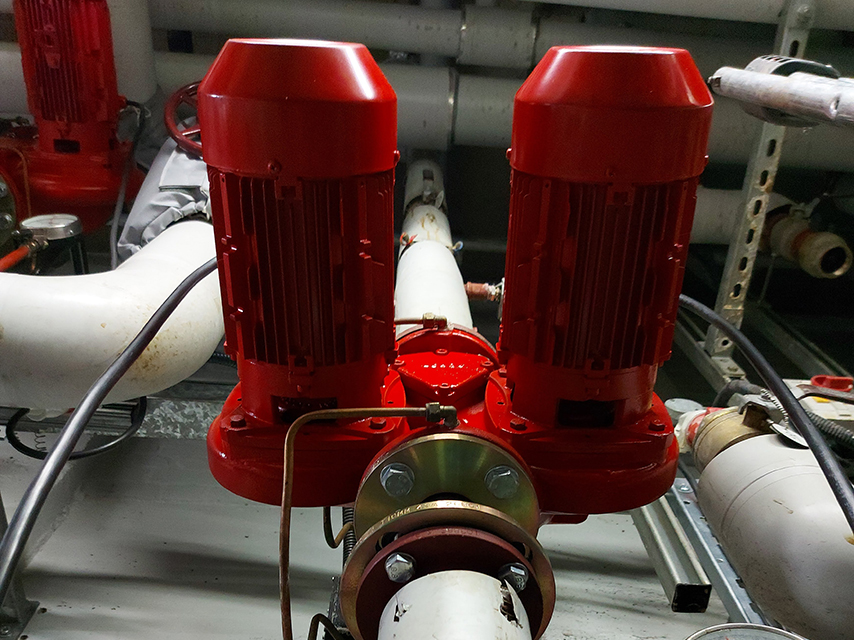

A range of inline Biral Redline centrifugal pumps at a constituent college of the University of Cambridge had reached the end of their life. Even though the pumps were still able to operate, their capacity was inefficient. If a breakdown had occurred, obtaining parts would be costly and some parts were obsolete and no longer manufactured/stocked.

The existing pumps were three-phase. However, any replacement CAN motor pumps are now only available in single-phase. The College requested that the system remain three-phase and wanted to be able to control the pumps through their Building Management System (BMS).

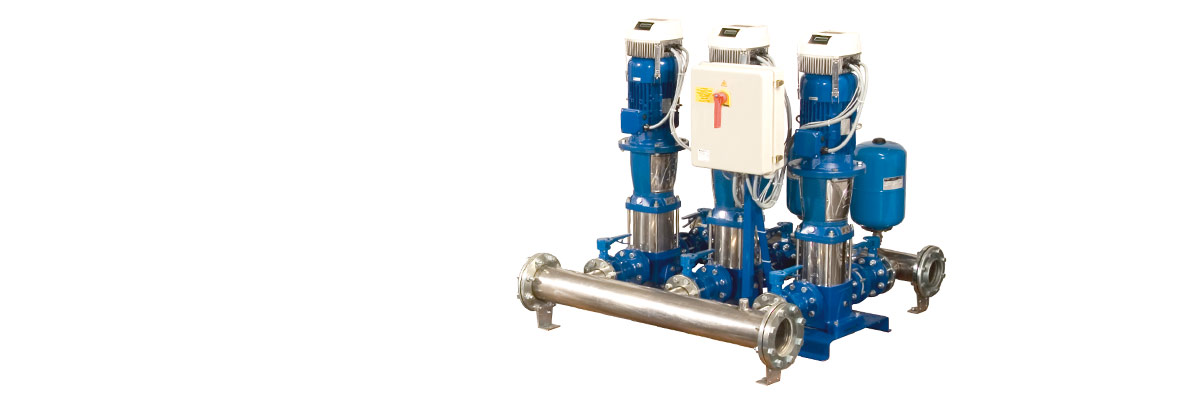

The Solution

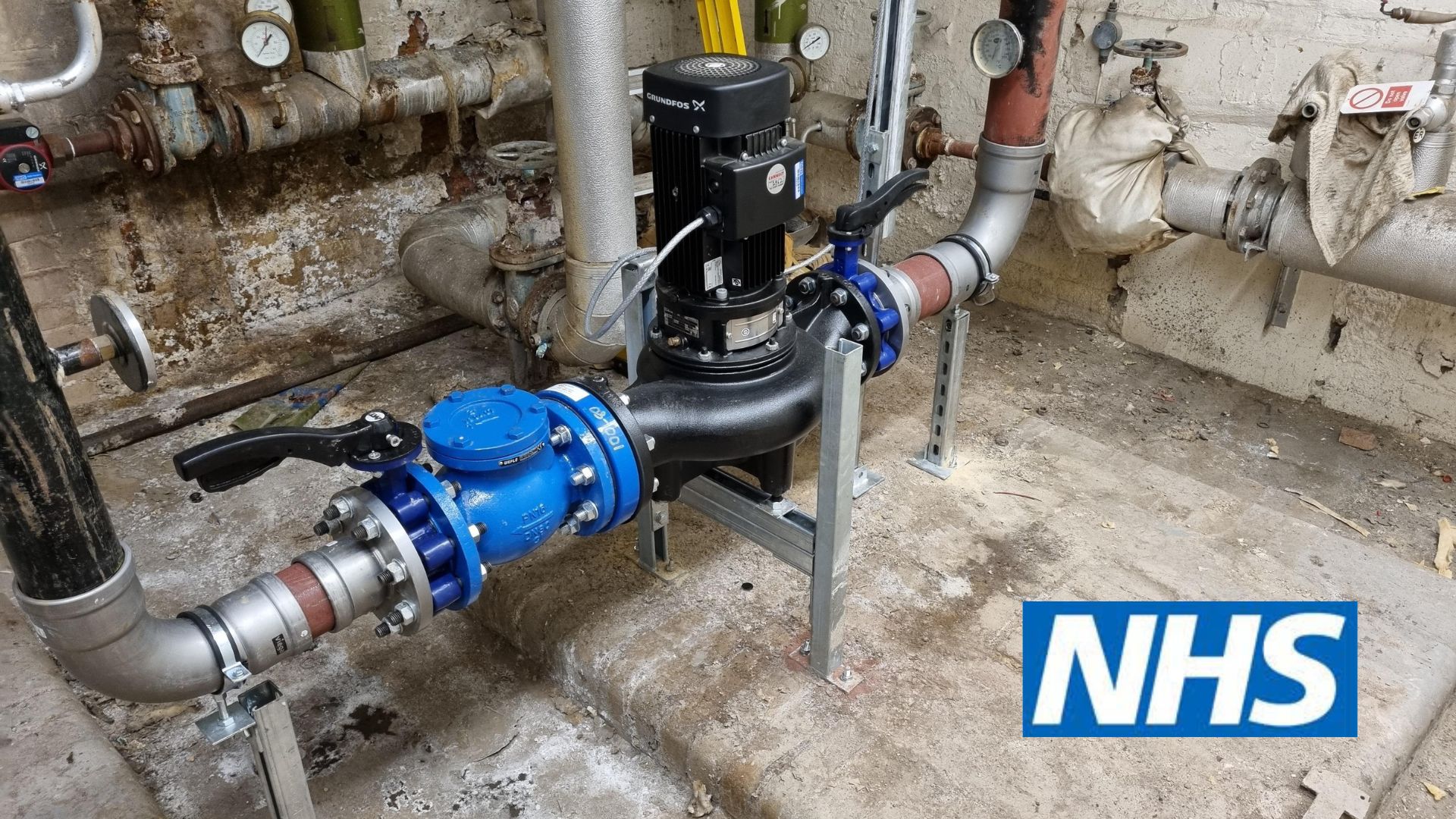

The Dura Pump experts assessed the demands of the College and utilised their extensive product knowledge and stock levels to find the best solution. A range of Kolmek inline centrifugal pumps, linked to Danfoss inverter drives, was installed. All pipework and electrical modifications were made to adapt the new pumps to fit into the existing system. This reduced disruption and ensured the process went smoothly.

The Danfoss inverter drives allow the system to continue to run on three-phase, whilst providing the College with the ability to control the system through their BMS.

Outcome

The benefits and results were simple:

- Increased reliability

- Increased control

- Standard components

All of these benefits were coupled with increased energy savings compared to the old pumps, providing the customer with a handsome payback. Although the initial outlay can sometimes appear costly, the benefits and energy savings of upgrading your system far outweigh that primary investment.

Key Points

- Easy to self-control and monitor.

- Latest technology used to deliver energy savings.

- Bespoke solution delivered.

Case Studies