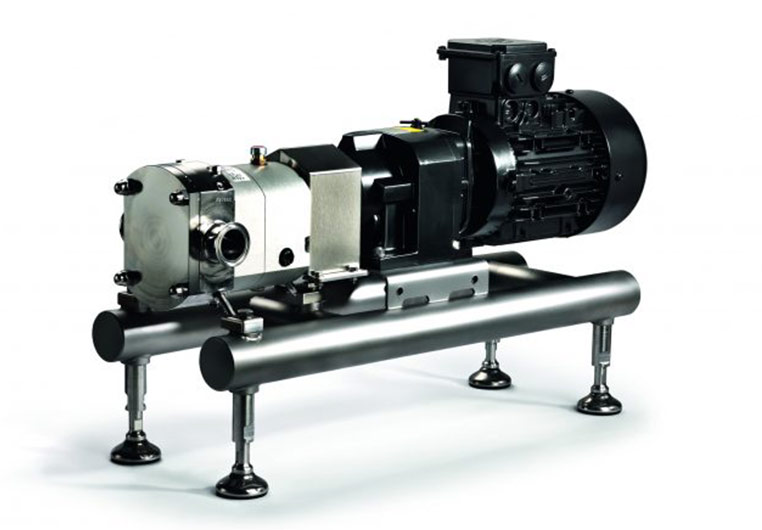

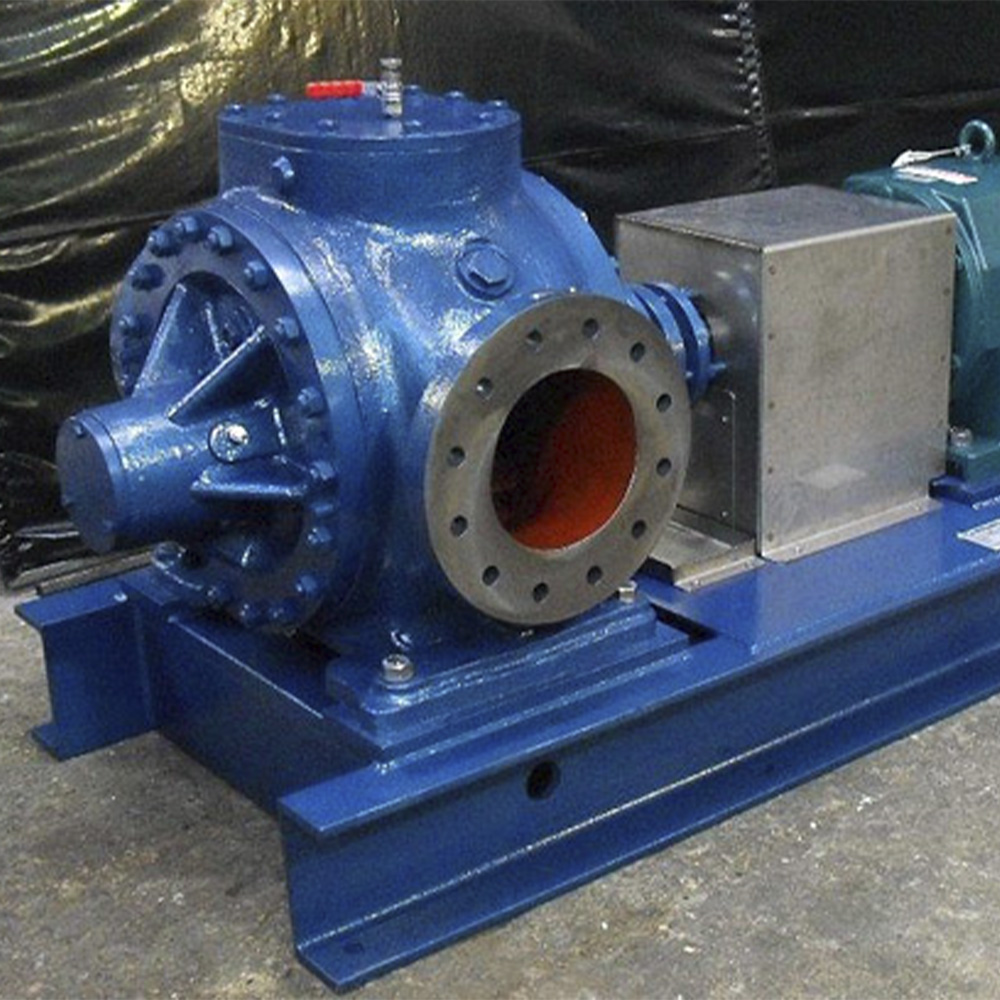

Lobe pumps are a positive displacement pump which consist of two rotors turning in opposite directions. A gearbox drives the rotors and provides synchronization and timing of the rotors. The two rotors spinning in opposite directions within the pump head carries the fluid through the pump in the cavities formed between the dwell of the rotor and the interior of the rotor case.

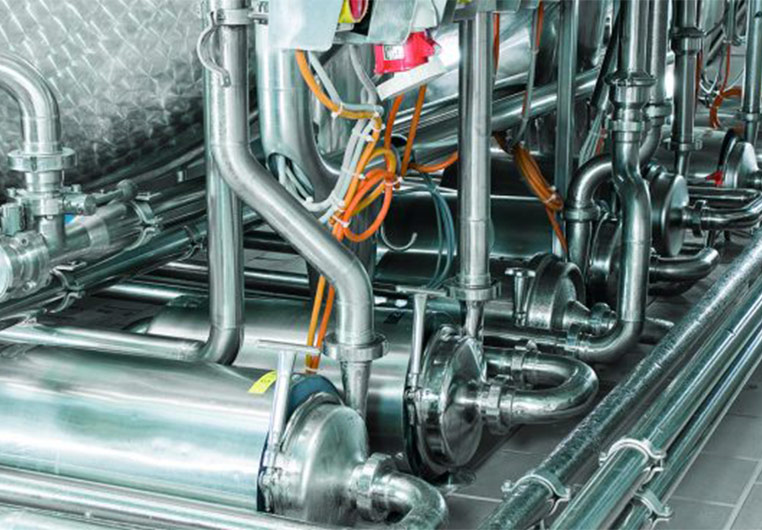

The pair of rotors create a vacuum on the priming side of the pump, drawing the fluids into the pump chamber the fluid is displaced with each rotation of the rotors. Lobe pumps offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.

Lobe pumps are available in a range of materials including rubber and stainless steel lobes, making them suitable for many applications.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800