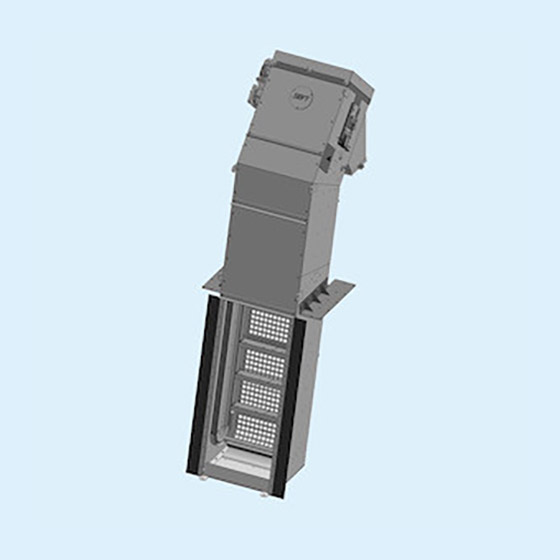

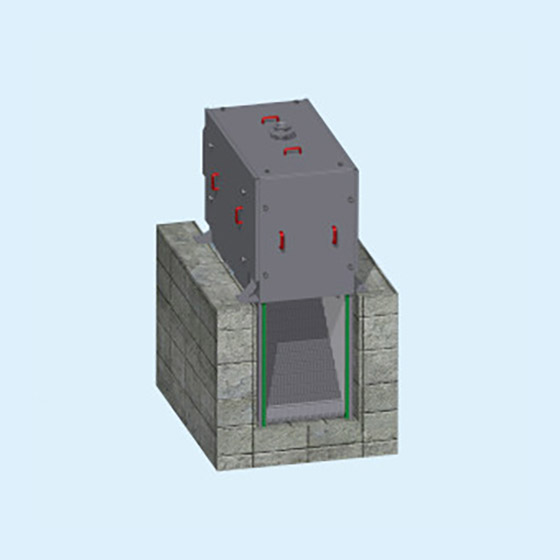

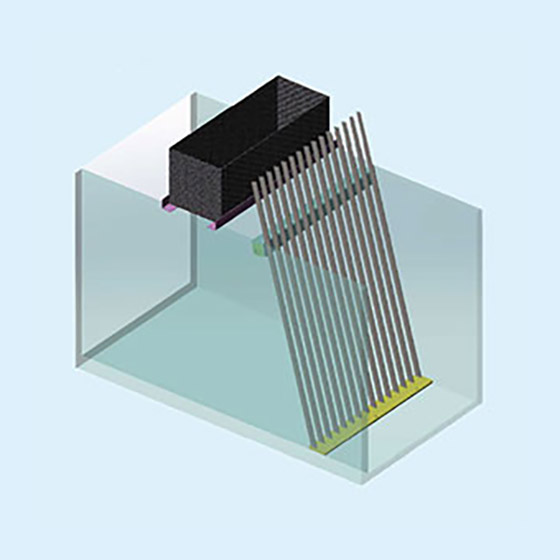

Seft’s bar screens are made to remove large solids that are within the waste water system. These screens use either bar, comb or chain rakes to remove the solids from the liquid. This range of Seft Bar Screens are made for course screening removing large solids however some smaller solids may still pass through. These screens are used on sites such as Slaughterhouses, Paper Mills and in the Food and Beverage Industries. These screens are made to be installed in a permanent situation and they are often made to size meaning the Bar screen will be specific to your system.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800