The V10 range of pump stations have been brought together by engineers who have owned, maintained, repaired, manufactured and designed pump stations. The concept behind our range is to provide the end user the most cost effective long-term solution for their application with a product that they understand.

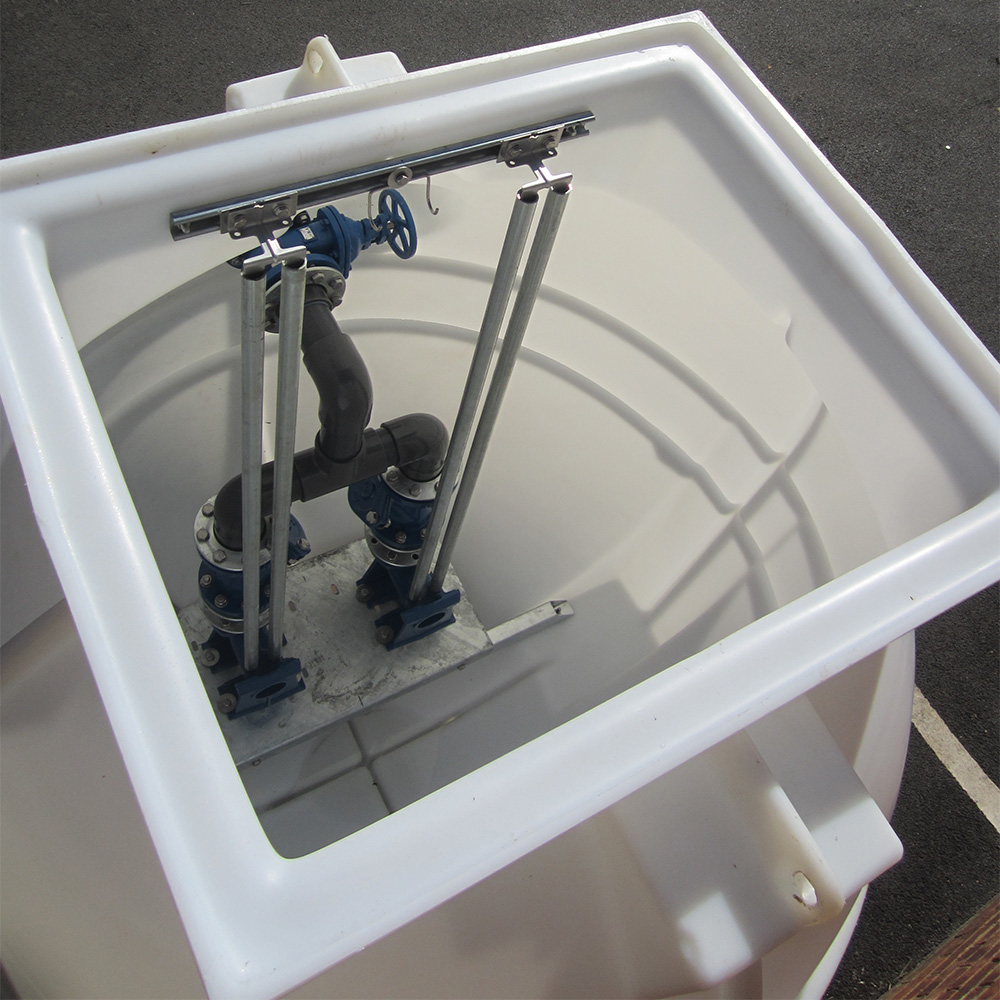

- Packaged pump station with all pipework and valves pre-installed before delivery to site, allowing quick installation and reducing labour time on site

- Robust tank made with high specification polyethylene, the material having excellent chemical resistance, stiffness and toughness. This provides prolonged outdoor protection.

- High quality pumps specified to suit your application that are energy efficient and will minimise the potential for blockages.

- Pumps mounted on guide rails for safe usage and easy maintenance.

- Heavy duty PVC pipe work will not rust, giving long-term reliability.

- Durable brass valves designed into the system to protect both the pumps and the system in the most cost-effective way.

- Tough floats control the waste water levels and provide early high level warning.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800