A Guide to Submersible Pumps

Posted on 18th March, 2024 by Dura Pump

Posted on 18th March, 2024 by Dura Pump

Anatomy, Application and Advantages: A Guide to Submersible Pumps

In the area of fluid dynamics, submersible pumps are unsung heroes, silently operating beneath the surface to power diverse applications ranging from groundwater extraction to wastewater management. In ‘ A Guide to Submersible Pumps’, we delve into the workings of submersible pumps, uncovering their design principles, applications, and the advantages they bring to industry.

Anatomy of a Submersible Pump

1. Encapsulation and Sealing:

The heart of a submersible pump lies in its hermetically sealed motor, encapsulated within a watertight housing. This design not only prevents water ingress but also shields the motor from external elements, ensuring durability, longevity and reliability.

2. Impeller Dynamics:

At the core, the impeller, often a multi-stage assembly, propels the fluid through the pump. Each stage imparts kinetic energy, pressurising the liquid for efficient extraction or transfer. With effluent waste the impellers are designed to transfer the solids without clogging up the pump. This can be done with a vortex impellor, a channel impellor or a grinder/cutter device. The correct selection of the impellor will provide maximum efficiency and minimal blockages.

3. Motor Efficiency:

Unlike traditional pumps, submersibles feature direct immersion in the fluid they handle. This proximity boosts heat dissipation, enhancing motor efficiency and minimising energy loss. The latest generation have integrated inverters to control the motors performance.

Anatomy of a Submersible Pump

- Encapsulating and Sealing

- Impeller Dynamics

- Motor Efficiency

Applications Beyond the Surface

1. Groundwater Management:

Submersible pumps are the backbone of groundwater extraction. Their ability to operate submerged ensures efficient and consistent water supply, crucial for water systems and industrial processes.

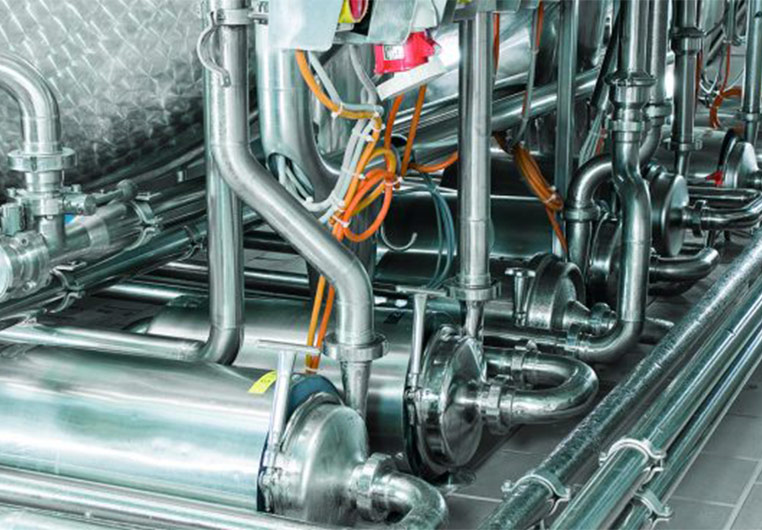

2. Wastewater Handling:

In wastewater treatment, submersibles excel. Their sealed design mitigates the risk of contamination, and their robust construction withstands the challenges of abrasive and corrosive effluents.

3. Sewage Pumping:

In sewage, pumps are designed to fully submerged, minimising the risk of leaks and preventing the escape of foul odours. They are equipped to efficiently manage solids. The impeller design allows for the passage of solids without clogging, ensuring a smooth and uninterrupted flow.

Application Beyond the Surface

- Groundwater Management

- Wastewater Handling

- Sewage Pumping

Advantages that Make Waves

1. Reduced Noise Pollution:

Submersible pumps operate quietly beneath the surface, minimising noise pollution. This makes them ideal for applications in residential areas and sensitive environments.

2. Space Efficiency:

Submersibles eliminate the need for extensive surface infrastructure because they live within the fluid they pump. This space efficiency is advantageous in small or aesthetically sensitive locations.

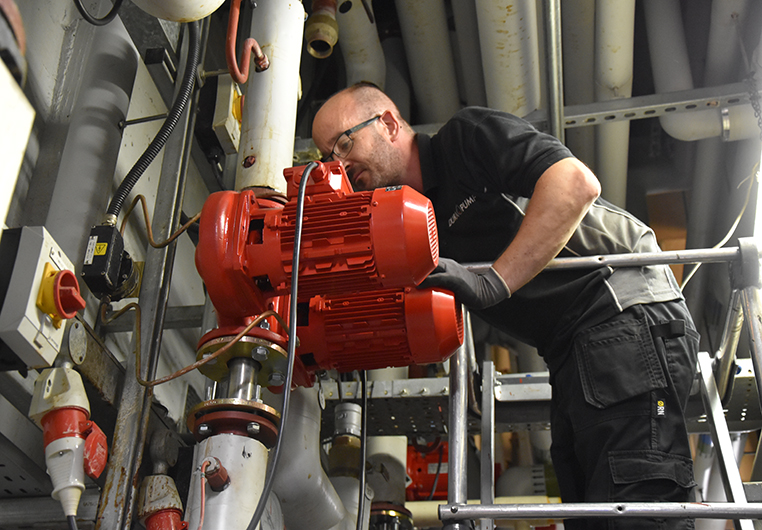

3. Lower Maintenance Requirements:

The submersible’s sealed design not only keeps contaminants at bay but also reduces maintenance needs. With fewer exposed components, these pumps display prolonged service life and reduced upkeep costs.

Advantages that Make Waves

- Reduced Noise Pollution

- Space Efficiency

- Lower Maintenance Requirements