Can Obsolete belt-driven pumps be repaired?

Posted on 11th May, 2023 by Dura Pump

Posted on 11th May, 2023 by Dura Pump

In a word – yes! But the real question you should be asking, is why?

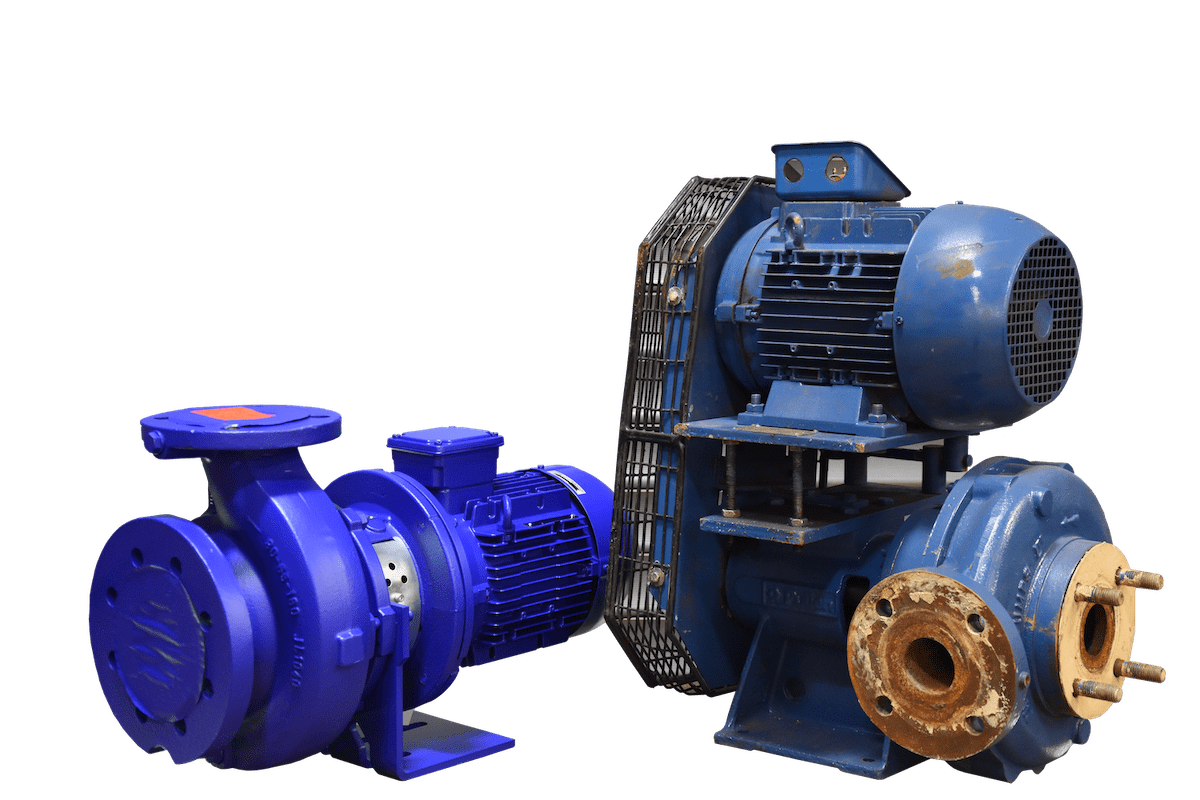

Belt-driven pumps are well known for their simplicity and ruggedness, qualities which have helped them to give reliable service in some cases for decades. Popular brands such as Pullen or Holden & Brooke are still a common sight in facilities all over the country, and they are a regular visitor to the Dura Pump workshop, for everything from simple seal replacement to a full reconditioning.

But in the years since these were first installed technology has moved on and although many users postpone their replacement as an unnecessary expense, there comes a time when it’s actually more cost effective to bring in something new. So why should you consider replacing your belt-fed pumps?

Greater energy efficiency

Modern pumps can often achieve the same results using a fraction of the power required by older belt-driven models, achieving savings of around 30-40%. One customer we fitted replacement pumps for went from using 37kW belt-driven pumps to more modern 18kW pumps, saving nearly 195,000 kWh of electricity and £65,000 per year. With ROIs like this modern pumps can often pay for themselves in less than 12 months.

More reliability

It’s a simple fact that the older a machine gets the harder it is to keep running in top-condition, and the more often it will fail. Newer designs have greater reliability and longer service intervals, helping you to minimise disruption and keep vital machinery running.

Greater spares availability

When the time does come for your machine to be serviced, old belt-driven pumps that have often been out of production for decades are increasingly difficult to find spare parts for, and those you can find will usually be second-hand with only a limited remaining useful life. Modern replacements with new parts still being made can avoid this issue, getting back up and running much faster.

Less noise

While it might not be the first thing you would think of, using quieter modern pumps can help keep a safer working environment for your staff. With hearing damage an occupational hazard in many plant rooms, staff must be provided with costly PPE to avoid liability on the part of their employers for a range of conditions. Many modern pumps mitigate noise generation considerably, compared to their ancestors which may have been designed fifty years ago.