Initial Situation

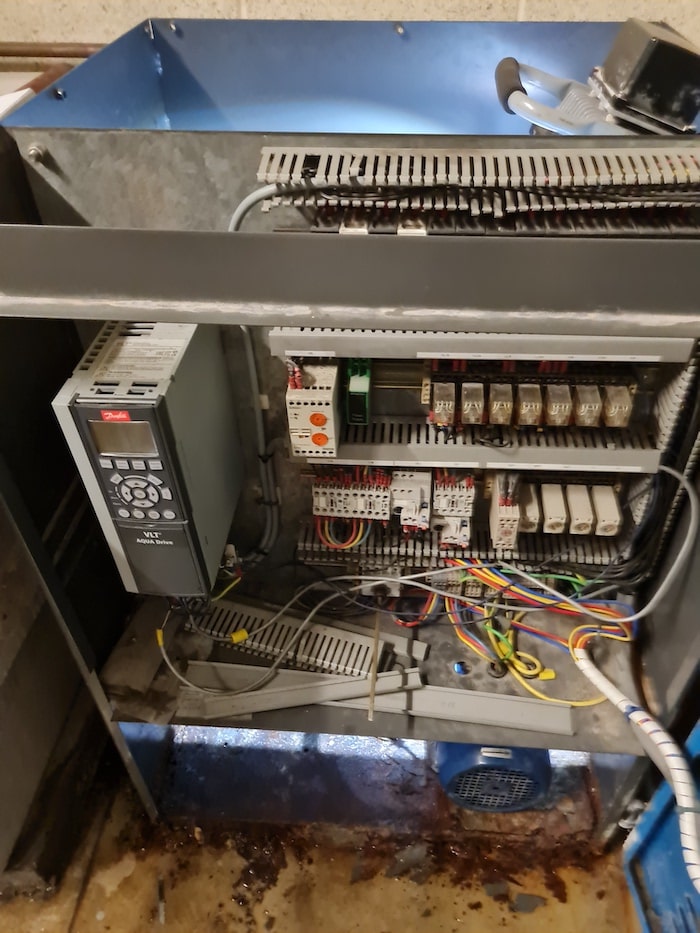

A food ingredients company approached Dura Pump due to issues with their process water booster set. The existing booster set suffered from unreliability due to outdated components and an inability to consistently meet the required water demand. Furthermore, the complex configuration of the booster set posed challenges for maintenance and repairs. The existing setup consisted of a fixed-speed, dual 3.0kW 400v pump arrangement configured for duty standby.

Proposed Solution

Dura Pump undertook a comprehensive evaluation of the situation and devised a tailored solution. The objective was to fulfill the company’s current water demand while fitting within the constraints of the available space. The recommended booster set featured a twin, variable-speed 2.2kW 400v unit. This advanced system was equipped with stainless steel manifolds, along with complete valve integration and a user-friendly control panel.

The installation was strategically scheduled to minimize disruptions to the factory’s production process. Dura Pump efficiently removed the old booster set and installed the new unit. This encompassed all essential tasks, including electrical, mechanical and pipework connections. Subsequently, the unit was commissioned to ensure seamless operation. Moreover, Dura Pump presented a transparent outline of maintenance schedule costs.

Outcome

The implementation of the new booster set ushered in a transformation for the food ingredients factory. The modern twin booster set is not only energy-efficient but also capable of reliably meeting the company’s water demand. The shift to the upgraded system led to a reduction in the need for frequent engineering attention. Consequently, the company now benefits from a sustainable and dependable long-term solution.

One of the supplementary advantages of the upgraded booster set is the notable energy savings achieved. Despite the reduction in pump power from 3kW to 2.2kW, the system manages to provide an increased flow rate and enhanced pressure levels. This dual benefit of energy efficiency and improved performance underscores the successful outcome of Dura Pump’s intervention.

Related Case Studies