The Challenge

This UK based European food supplier was operating belt-driven rotor jet pumps on their washdown set that were moving toward the end of their operating life. These types of pumps use old technology and need constant repair and maintenance which makes them costly and unreliable.

The Solution

Dura Pump conducted a full site visit to work on a bespoke specification for this complex washdown system.

The site was running on two 45kWh pumps which were wasting money for the customer. We recommended that they be replaced with an upgraded 11kWh quad washdown system.

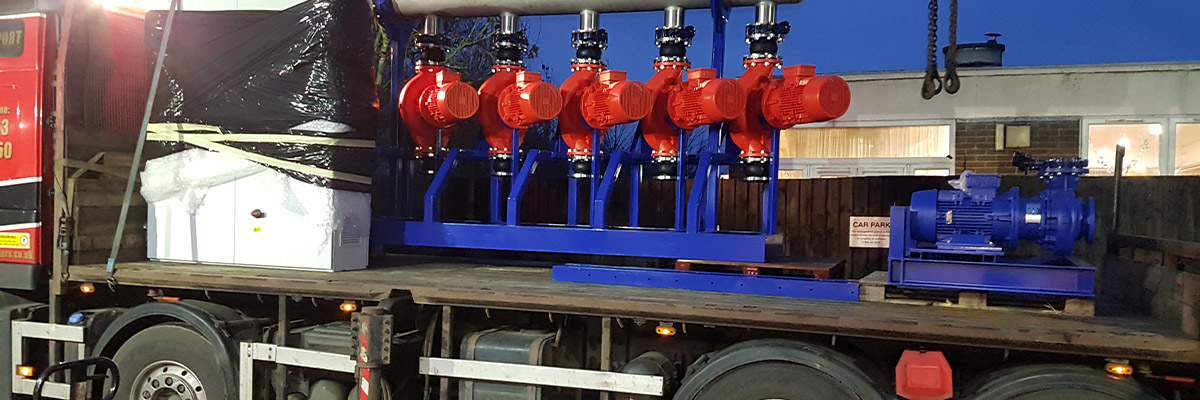

We proposed to use four Grundfos CRNE pumps running at 25 bar with a variable speed inverter to increase efficiency. The benefit of having four pumps for this customer was reliability – this allows the pumps to work continuously even if one or two pumps fail, meaning no downtime.

Downtime in food manufacturing can cost a company millions and has a significant impact on productivity and profitability, so alongside recommending the quad system, we also installed it at the weekend to minimise disruption.

Outcome

We delivered a successful design and installation of a reliable, cost saving and energy efficient system for our customer.

This was a full-service bespoke solution aimed at reducing repairs, time and costs by using the latest energy efficient technology.

The newly installed system will save the customer 224,988.68 kWh per year.

Key Points

- We delivered a successful design and installation of a reliable, cost saving and energy efficient system for our customer.

- This was a full-service bespoke solution aimed at reducing repairs, time and costs by using the latest energy efficient technology.

- The newly installed system will save the customer 224,988.68 kWh per year.

Related Case Studies