The Challenge

The proper and efficient use of a chilled water system is crucial – especially where natural water reserves are used to precool the chiller units. In a recent project on behalf of a local council authority, the team at Dura Pump were called upon to help out with a faulty chilled water system that followed this process.

As is the case with many chilled water systems throughout the UK, this local council building was using water from surrounding rivers to pre-cool their chiller units. However, despite the customer’s use of a water filter, they experienced continuous blockages in their system due to sediment from that same river.

This blockage due to river sediment created significant problems for our customer. Whilst it was curtailing efficiency and leading to costly maintenance and repairs, the blockage combined with old, PVC-manufactured pipework to cause turbulence throughout the system.

The challenge was clear. It was time that Dura Pump got to work doing what it does best!

Our Solution

No problem is too big for the team at Dura Pump, and we were delighted to lend the customer our expertise for this complex chiller unit issue. Following initial conversations, our team of engineers visited the site of the local council building to take key measurements and to assess the problem at-hand. This enabled us to provide a solution that would work within any spatial, budgetary or operational requirements.

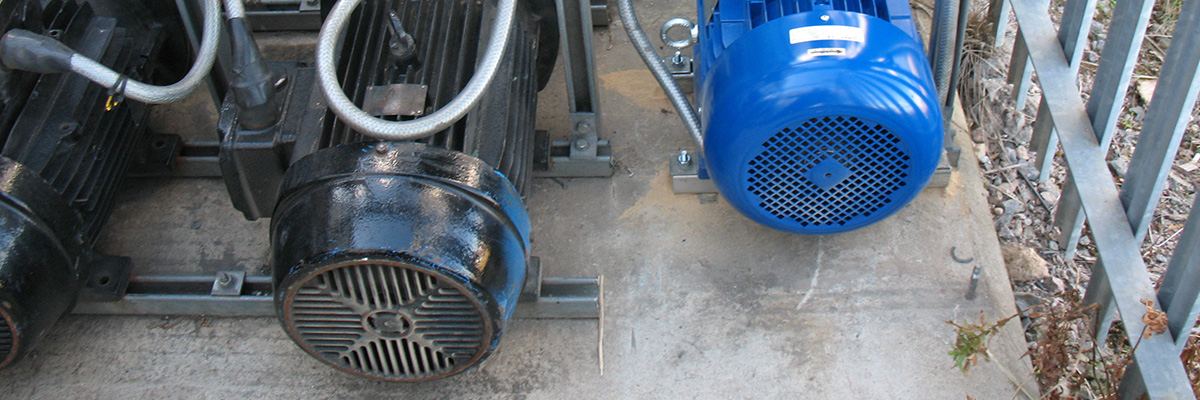

After the consultation stage, we got to work in delivering a permanent and effective solution to this problem. To get started, it was decided that the circuit of river water would have to be split apart from the water circulating through the chillers. To achieve this, Dura Pump installed a 30Kw inverter-driven pump to draw water from the river through a filter. From that point, the water was circulated through a heat exchanger; cooling the building’s water and transferring the heat back to the river. This was all done without allowing the dirty water to contaminate the water passing through the chillers.

For the next step in this project, Dura Pump reconnected the pumps that were being used to move the river water into the chillers to the opposite side of the new heat exchanger, circulating the clean water through the chillers as a result. Meanwhile, the river pump in this instance was a variable speed pump running on differential temperatures’ maximising the efficiency of the pump and the overall durability of the system.

Beyond these actions, Dura Pump took a major step in transforming this situation by installing new, stainless steel pipework ranging from 10’’ – 2 1/2’’ throughout the system. By installing new pipework with cone reducers and eliminating the sharp elbows, we minimised the resistance and turbulence from the system.

Another job well done!

The Results

Following the successful completion of this project, Dura Pump were delighted to deliver a number of positive results. Whilst the customer was now able to work using a more reliable and blockage-free system, they were also able to note a decrease in their carbon emissions thanks to boosted efficiency.

The customer has now found that they have had an increased flow; meaning they can experience improved cooling throughout the building. Beyond this significant benefit, the reduced turbulence experienced after replacing the pipework means there is less strain on the system – as well as less maintenance requirements.

- Improved reliability

- Improved flow

- Improved efficiency

- Reduced maintenance

Related Case Studies