The Challenge

A public school in Buckinghamshire reached out to us with a critical issue surrounding their triple cold water booster set. While the pumps themselves were in good condition, the aging control panel posed a potential threat. If not addressed, the obsolete control panel could lead to a system failure, leaving the school without water until repairs were made.

The Solution

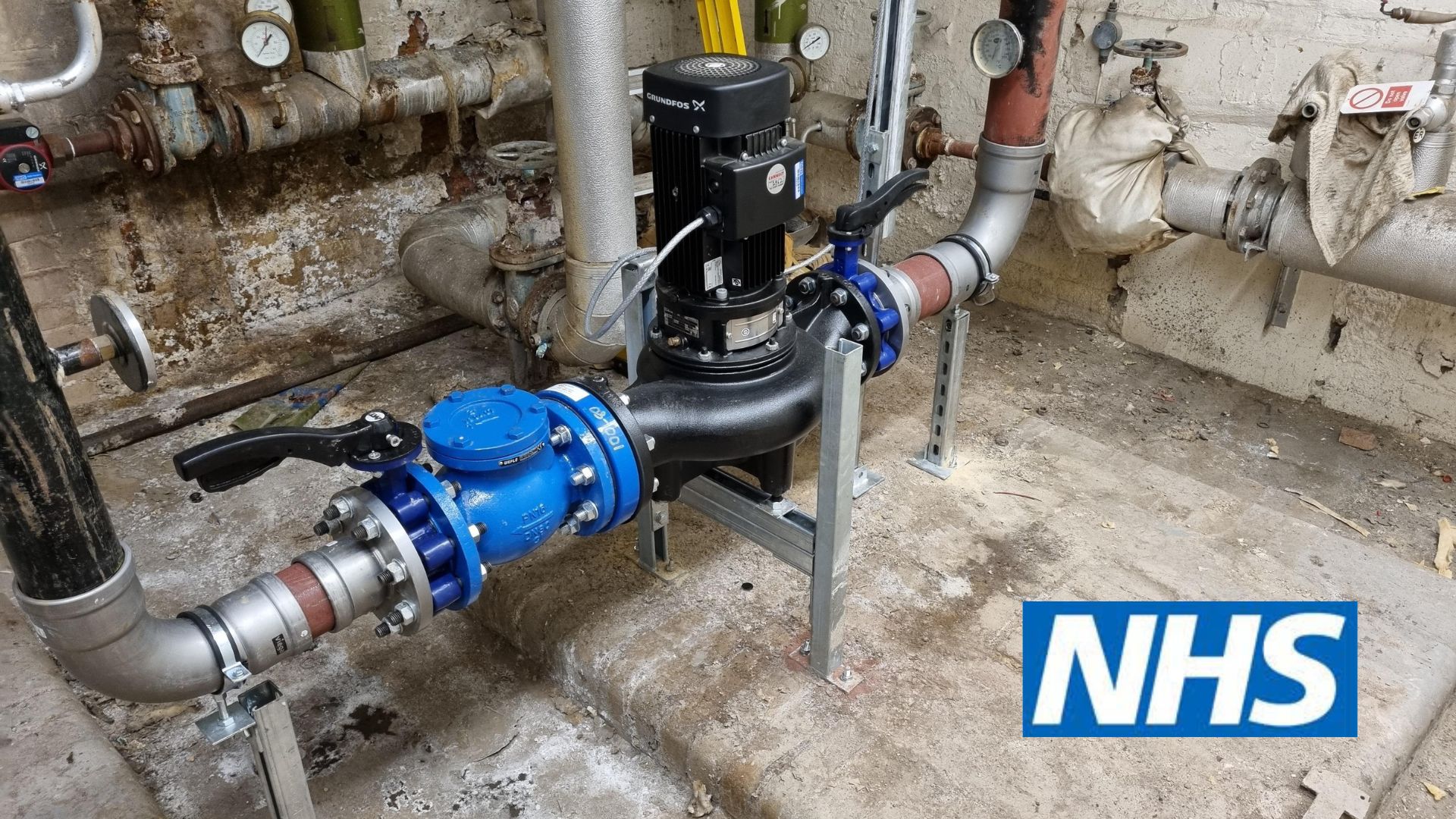

Our team of experts recommended, sourced, and installed a new energy-efficient Variable Frequency Drive (VFD) control panel. This innovative solution is designed to control the motor and feed pump speed, optimising power consumption by reducing it when not needed. The fully adjustable control panel allows for easy management of starting, stopping, and acceleration.

In addition to the control panel upgrade, our team identified that the inverters on the pump were obsolete. We replaced these components, ensuring a comprehensive and future-proof solution for the school.

Outcome

The result of our intervention was that the cold water supply to the school continued without interruption, eliminating the threat of a system failure. Looking ahead, the upgraded pump system promises increased efficiency as the customer gains control over water flow to meet demand, rather than operating at a constant pressure. This strategic adjustment is anticipated to yield significant cost savings over time.

Key Points

- Cutting-Edge Technology: The installation of the latest energy efficient VFD control panel ensured optimal performance.

- Minimal Disruption: Our team worked outside regular hours to minimise any disruption to the school day.

- Prevented System Failure: By addressing the aging control panel proactively, we averted the risk of a complete pump failure.

Related Case Studies