|

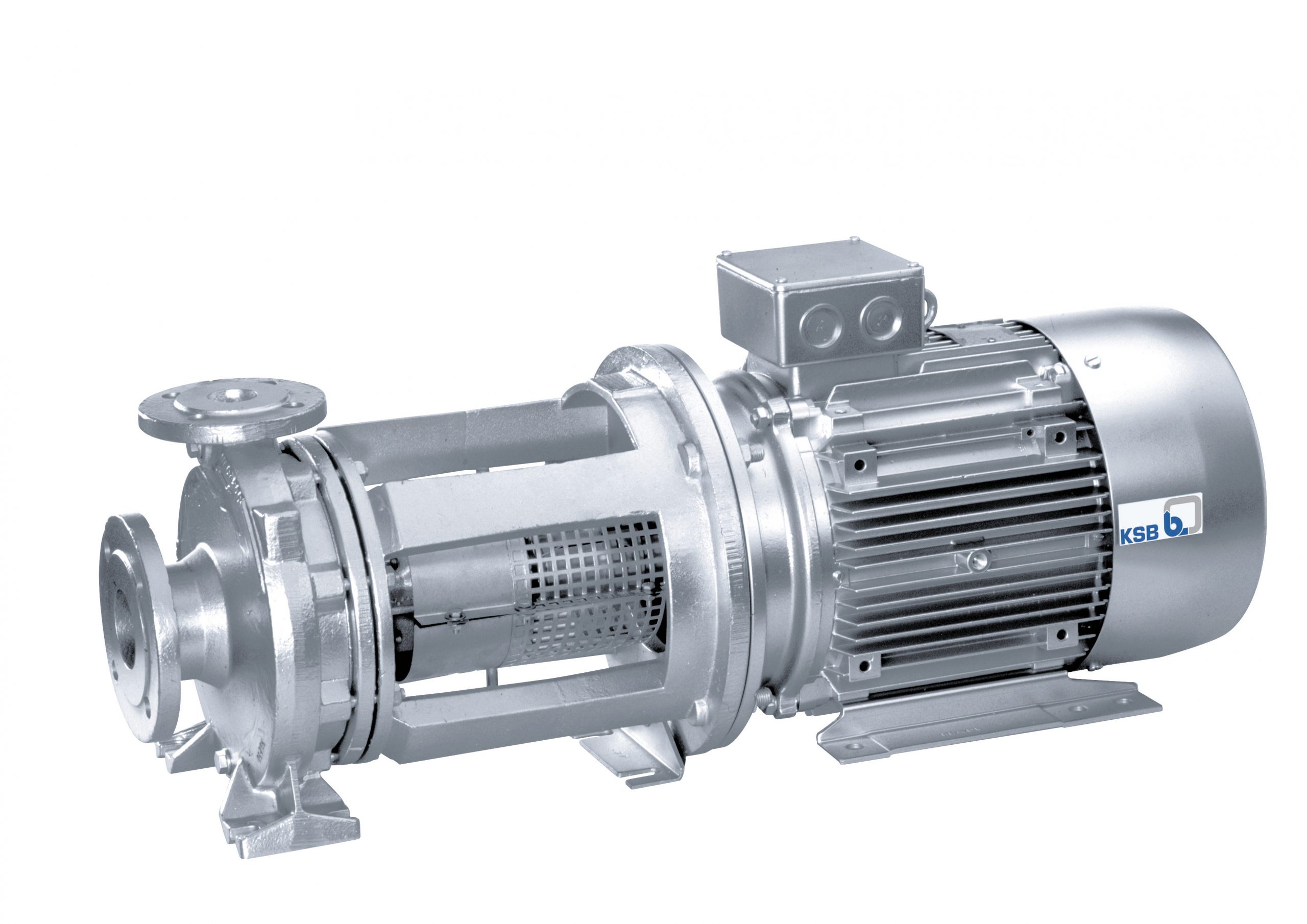

CPKN

Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to ISO 2858 / ISO 5199. Also available as a variant with "wet" shaft, conical seal chamber and/or semi-open impeller (CPKNO). ATEX-compliant version available.

|

Flow & Head

Max Flow: 4800 m³/h

Max Head: 275m |

Downloads

cpkn-cpk-d-hpk-l-magnochem-bloc-1

|

|

Emporia CP

Single-stage centrifugal pump in close-coupled design, extremely quiet operation, for use in domestic, public and industrial applications.

|

Flow & Head

Max Flow: 7.5 m³/h

Max Head: 55m |

Downloads

emporia-cp-2

|

|

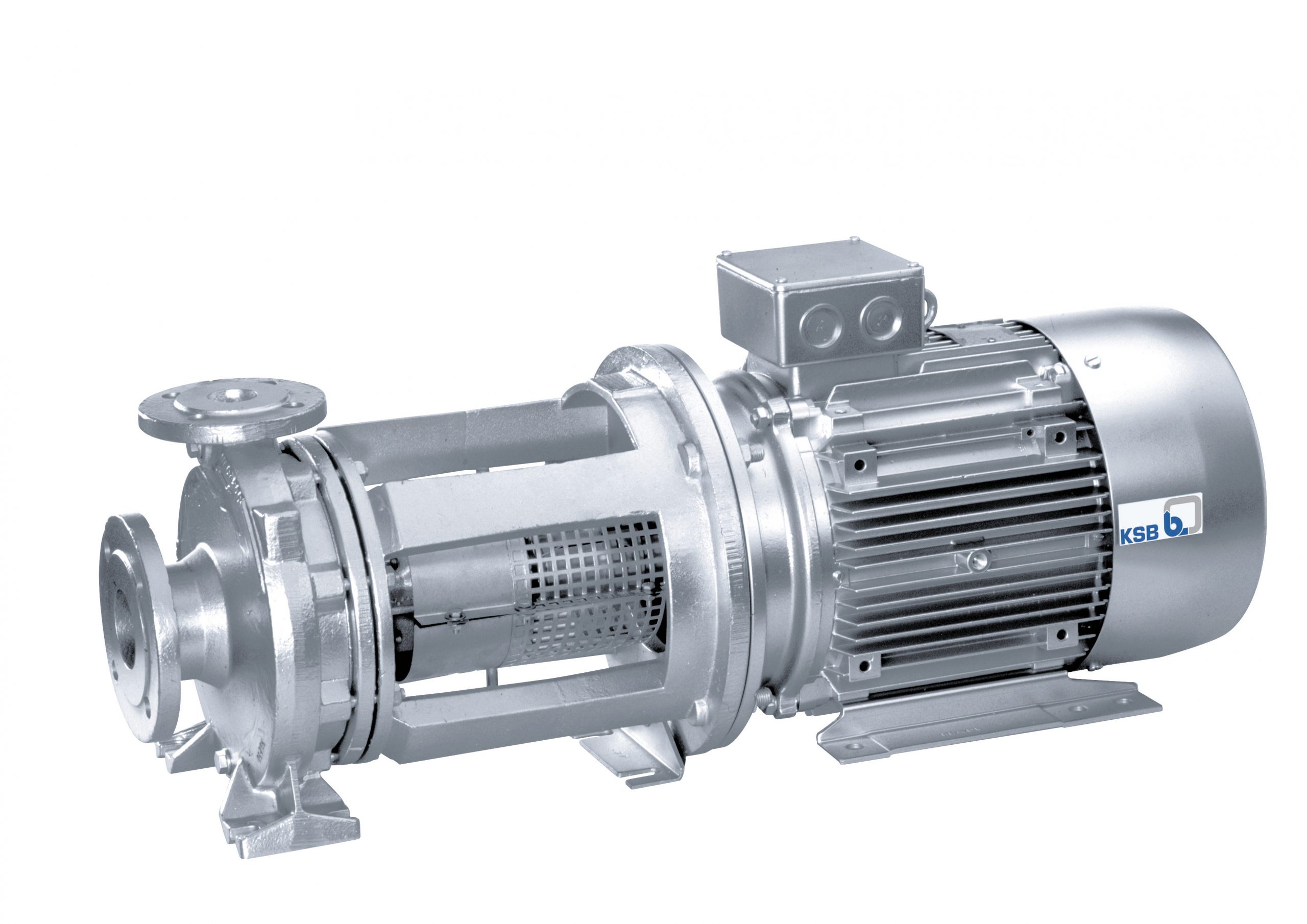

Etabloc

Single-stage close-coupled volute casing pump, with ratings to EN 733, with replaceable shaft sleeve and casing wear rings, with motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation with the KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

|

Flow & Head

Max Flow: 740 m³/h

Max Head: 160m |

Downloads

etabloc-curves-booklet-2-1

|

|

Etabloc SYT

This high temperature Etabloc pump is suitable for pumping high temperature liquids from 120°C and upward. This is a long coupled design with a back pull-out design meaning it can be easily maintained. This single-stage centrifugal pump uses KSB's SuPremE motor which is in the IE4/IE5 efficiency class meaning the pump is rated to EN 733 standards.

|

Flow & Head

Max Flow: 337M3/h

Max Head: 99m |

Downloads

etabloc-syt-product-description

|

|

Etachrom B

Horizontal single-stage close-coupled annular casing pump, with ratings and main dimensions to EN 733, with replaceable casing wear rings and motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation with the KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

|

Flow & Head

Max Flow: 260m3/h

Max Head: 105m |

Downloads

etachrom-l-_-etachrom-b_-50-hz-60-hz

|

|

Etachrom L

Horizontal single-stage annular casing pump, with ratings and main dimensions to EN 733, with replaceable casing wear rings and motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation with the KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

|

Flow & Head

Max Flow: 260m3/h

Max Head: 105m |

Downloads

etachrom-l-_-etachrom-b_-50-hz-60-hz

|

|

Etanorm

Horizontal volute casing pump, single-stage, with ratings and main dimensions to EN 733, long-coupled, back pull-out design, with replaceable shaft sleeves / shaft protecting sleeves and casing wear rings, with motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation with the KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

|

Flow & Head

Max Flow: 740m3/h

Max Head: 160m |

Downloads

etanorm-2

|

|

Etanorm SYT

This Etanorm horizontal volute casing pump is designed to pump high temperature liquids from 120°C and upward. It is a centrifugal pump what many different features such as the split volute casing, and a double mechanical seal to EN12756 standards. This pump is fitted with the KSB SuPremE magnetless motor meaning it is highly efficient and reliable. The pump is a variable speed system meeting the EN733 ratings.

|

Flow & Head

Max Flow: 2280m3/h

Max Head: 101m |

Downloads

etanorm-syt-infoamtion

|

|

Etanorm R

Horizontal long-coupled, single-stage (two-stage for pump size 125-500) volute casing pump in back pull-out design, with replaceable shaft sleeves / shaft protecting sleeves and casing wear rings, with magnetless KSB SuPremE motor of efficiency class IE4/IE5 and PumpDrive variable speed system; ATEX-compliant version available.

|

Flow & Head

Max Flow: 2285m3/h

Max Head: 101m |

Downloads

etanorm-r-2

|

|

Etanorm RSY

Horizontal volute casing pump in back pull-out design, single-stage, with ratings and dimensions to EN 733, radially split volute casing with integrally cast pump feet, replaceable casing wear rings, closed radial impeller with multiply curved vanes, single mechanical seal to EN 12756, double mechanical seal to EN 12756, drive-end bearings: rolling element bearings, pump-end bearings: plain bearings, with magnetless KSB SuPremE motor of efficiency class IE4/IE5 and PumpDrive variable speed system; ATEX-compliant version available.

|

Flow & Head

Max Flow: 2285m3/h

Max Head: 101m |

Downloads

etanorm-rsy-2

|

|

HPK-L

This is a horizontal centrifugal pump which is made to transport high temperature liquids around a system. It is made to work with liquid that is 120°C and upward. This pump is fitted with a heat barrier and seal chamber to reduce the heat that gets to the motor. The motor is cooled like most motors with a fan attached to the end of the shaft, this therefore means it needs no external cooling.

|

Flow & Head

Max Flow: 1400m3/h

Max Head: 400m |

Downloads

cpkn-cpk-d-hpk-l-magnochem-bloc-1

|

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800