The pressurisation set is controlled with switches that detect system pressure and engage the pumps when pressure is lost. A pressurisation set is linked to a closed system at a neutral point. This point is not impacted by the duty of a system pump.

Pressurisation units are designed to replace water that has been lost through system leakage, to maintain the system design fill-pressure in sealed heating and chilled water systems and to provide safety circuits locking out the chiller unit or boiler in the event of extreme pressures.

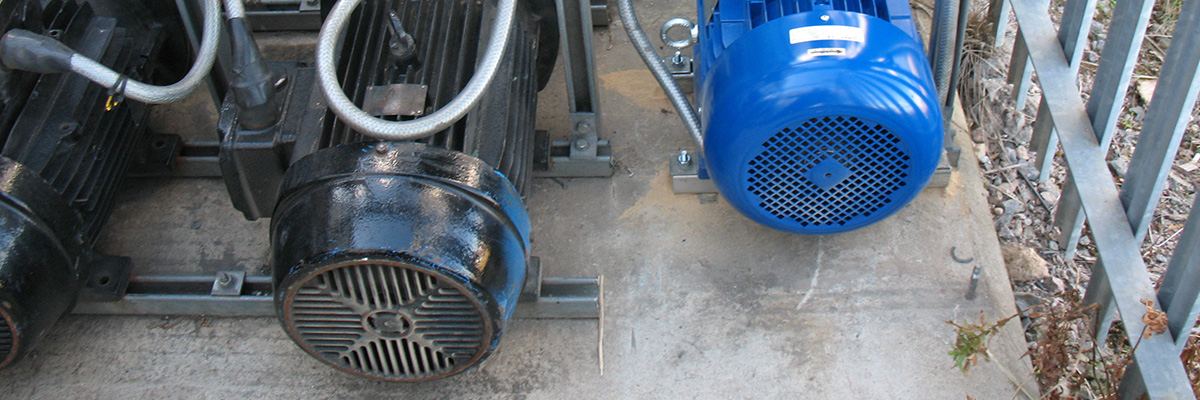

They lower the risk of pressure being too high or low, stopping knock-on effects on the day-to-day operation of premises. Linked to the pressurisation sets there is also pressure vessel, to take up the expansion in the system. These sets have a small CAT5 break tank with one or two small peripheral pumps throughout the system to maintain pressure. Sometimes pressurisation sets are also known as fill and spill systems and vice versa. Fill and spill systems are typically found on larger applications. In principle the systems work the same, however a pressurisation set doesn’t have a spill system, it uses a pressure vessel instead.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800