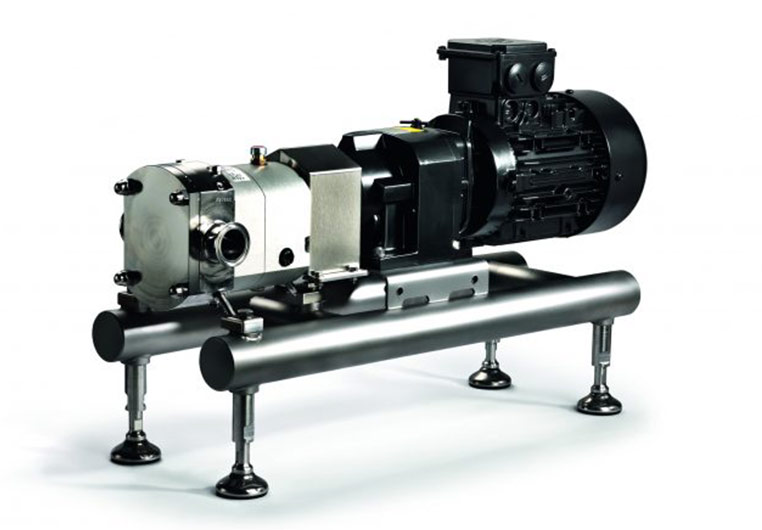

Progressive cavity pumps have a main function of transferring fluids by progressive means through a sequence of cavities as its rotor turns. Progressive cavity pumps are mainly used for pumping of viscous materials and fluid metering.

Progressive cavity pumps are commonly known by several different names such as, helical roto pumps, mono pumps, positive displacement pumps or rotor pumps. These pumps have been designed to convey shear-sensitive, frothing, abrasive, heterogeneous and viscous liquids. The longer the rotor of these units, the higher the head of the pump will be.

The pumping element comprises of a precision machined single external helic metallic rotor, and a double internal helix elastomer stator. Due to the special profile of the rotor and rotor set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions.

As the rotor turns within the stator, these cavities progress from the suction to the discharge end of the pump carrying the fluid. Flow is directly proportional to speed meaning they can be used to meter fluids.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800