Twin screw pumps fall within the group of positive displacement pumps often used for hygienic applications. Originally, these pumps were used for the transportation of oil products. However in recent years they have become popular in the food and beverage industries, pharmaceuticals, cosmetics and fine chemicals.

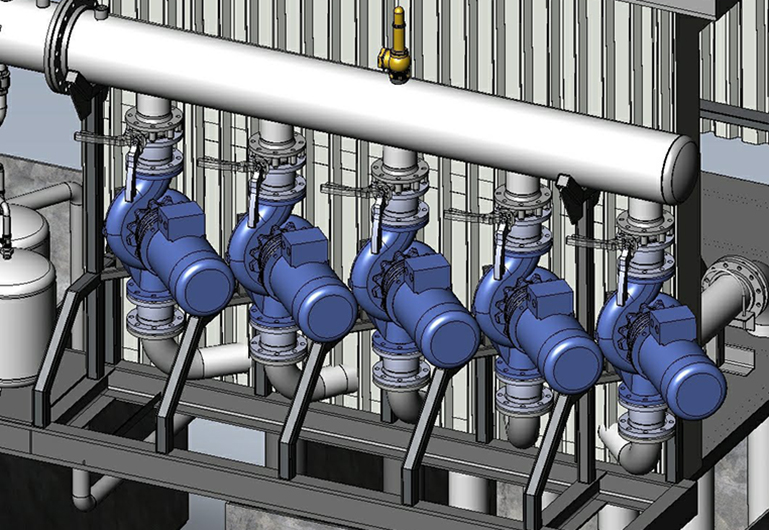

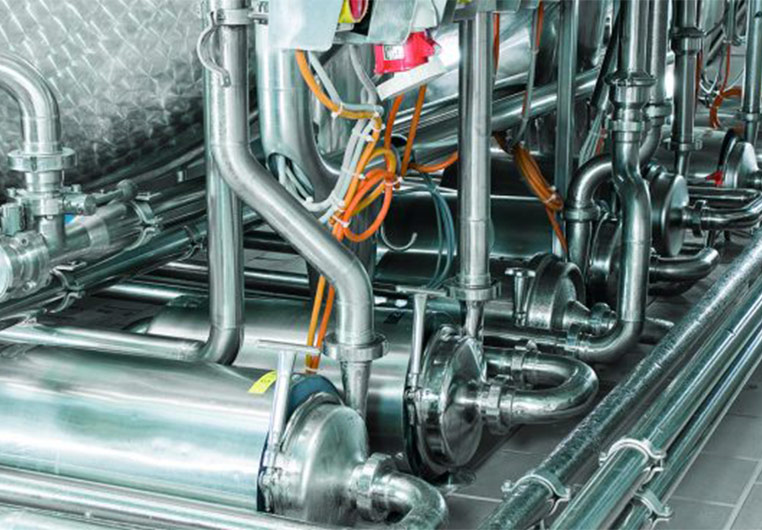

Some versions are entirely of stainless steel while other non-hygienic could be made from steel/cast iron. The standard design of the twin screw pumps is a two spindle version. A left and a right-hand feed screw displaces the product in the axial direction. The non-contact running screws are very resistant to wear, giving them greater durability which in turn reduces the maintenance required.

Since the product is not spun but deflected in the direction of rotation, the product transfer is very gentle. The pumps also work with low pulsation to protect the product and associated plant.

They have excellent priming ability, which is accompanied by low NPSH values which helps to avoid cavitation. The same pump can transfer low and high viscosity products and also products with entrained air.

They are designed to handle solids of up to 50mm without damaging the product. Double flow high-pressure twin screw pumps are available for differential pressures of up to 50 bar. Twin screw pumps are available with hygiene certification. CIP cleaning can also be performed with the same pump resulting in saving space and money because there is no requirement to install a second pump for the CIP process.

The mechanical seals are robust and wear resistant and are available in single or twin seal design, with flush facility where required. The seal specification can meet all hygienic demands, where applicable. They are used in many applications. The following are a few examples; Cheese spread, pastes, viscous dough, meat emulsion, whole egg, frozen orange juice concentrate, yeast cultures, creams, toothpaste, body lotions and medicines.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800