The Challenge

In the dynamic world of food manufacturing, even the smallest procedural changes can lead to unforeseen challenges. One of our valued clients in the industry encountered such a hurdle when modifications in their process caused temperature fluctuations, thickening their gravy and, consequently, causing failures in their hygienic centrifugal pumps.

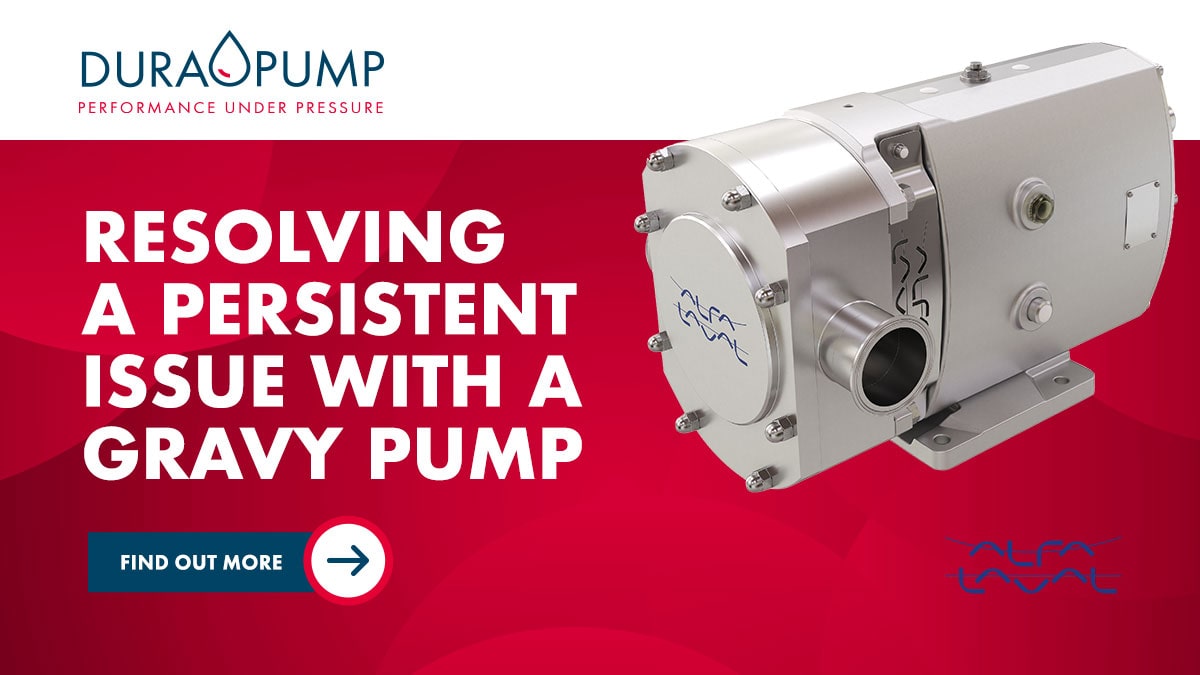

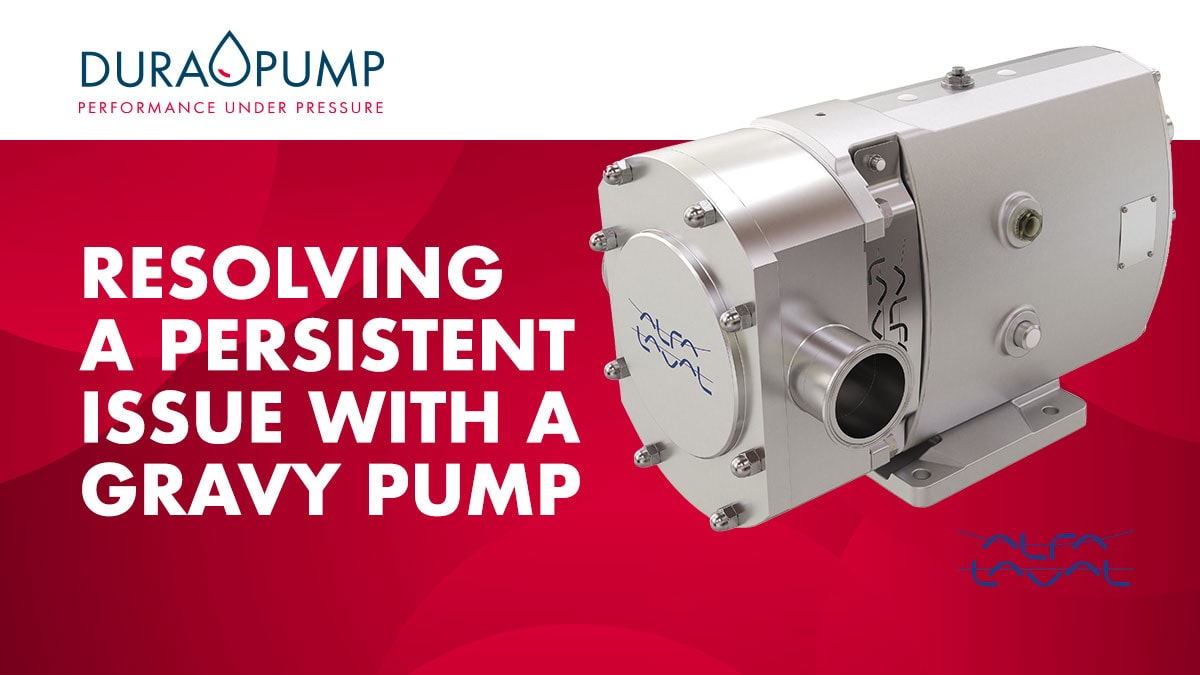

Proposed Solution

Our dedicated technical team faced the task of not only identifying a pump that could seamlessly integrate into the existing setup but also doing so within a short timeframe to minimize downtime. After careful consideration, the team proposed the implementation of an Alfa Laval hygienic lobe pump.

Outcome

This pump proved to be a game-changer, addressing the viscosity challenges posed by the cooled gravy and accommodating the higher temperatures during peak production. Its compact design allowed it to fit snugly into the available space with minimal pipework modifications, ensuring a smooth transition. The key advantage was its availability, with the pump ready for installation within just one week, significantly reducing downtime.

The successful integration of the Alfa Laval pump resulted in a remarkable improvement in our client’s production efficiency. Pump failures on the gravy line became a thing of the past, alleviating stress for the engineering manager and saving valuable engineering time. This case exemplifies how a strategic pump solution can not only resolve operational challenges but also contribute to enhanced productivity and reduced downtime in the food manufacturing sector.

IF YOU BELIEVE PROACTIVE MAINTENANCE COULD BENEFIT YOUR ORGANIZATION, PLEASE DON’T HESITATE TO CONTACT US AT 01604 648800.

Related Case Studies