The Challenge

This UK-wide pet food manufacturer wanted to solve their problem of too much water being wasted on the production line. They contacted us to find out what solutions were available.

The Solution

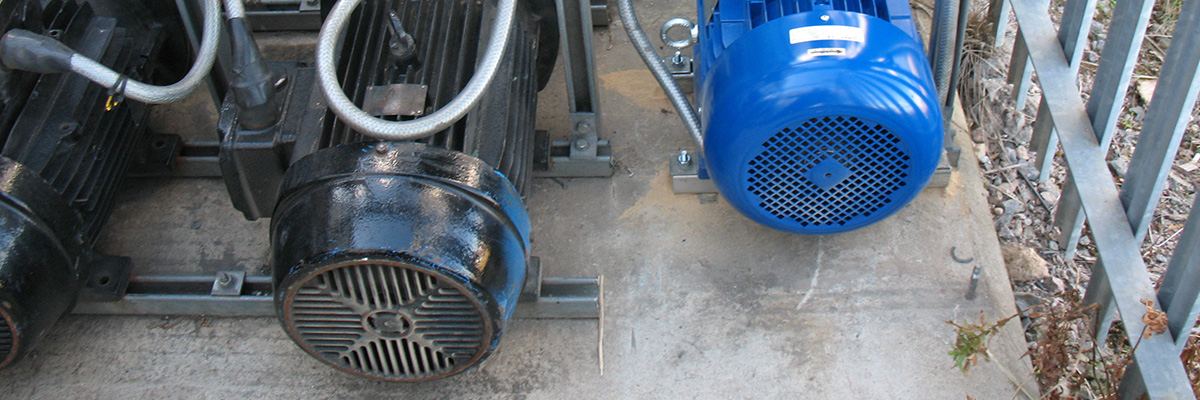

The new bespoke system had to fit in with the current production line, so we recommended a simple but effective low-level tank and pump system that could fit under the existing canning line.

The system consisted of a stainless-steel tank which does not rust or cause contamination, a Grundfos multistage pump, valves, pipework and control panel. The control panel can be operated by hand or on automatic with run and trip lights.

The system takes the cooling water from the production line which is currently going to waste and recycles it back into the chilled water system to save wastage of water.

We prebuilt and tested the system off-site and conducted the installation outside of operational hours, minimising downtime.

Outcome

We delivered a successful design and installation of a reliable, water-saving solution for our customer.

This was a tailor-made solution aimed at saving on fresh water and reducing wastewater.

Key Points

- Tailored pump system delivered for our customer.

- Reduced water consumption.

- Designed to fit into the existing production line with no disruption.

Related Case Studies