Are persistent pump issues a problem in your food processing?

Posted on 22nd February, 2024 by Dura Pump

Posted on 22nd February, 2024 by Dura Pump

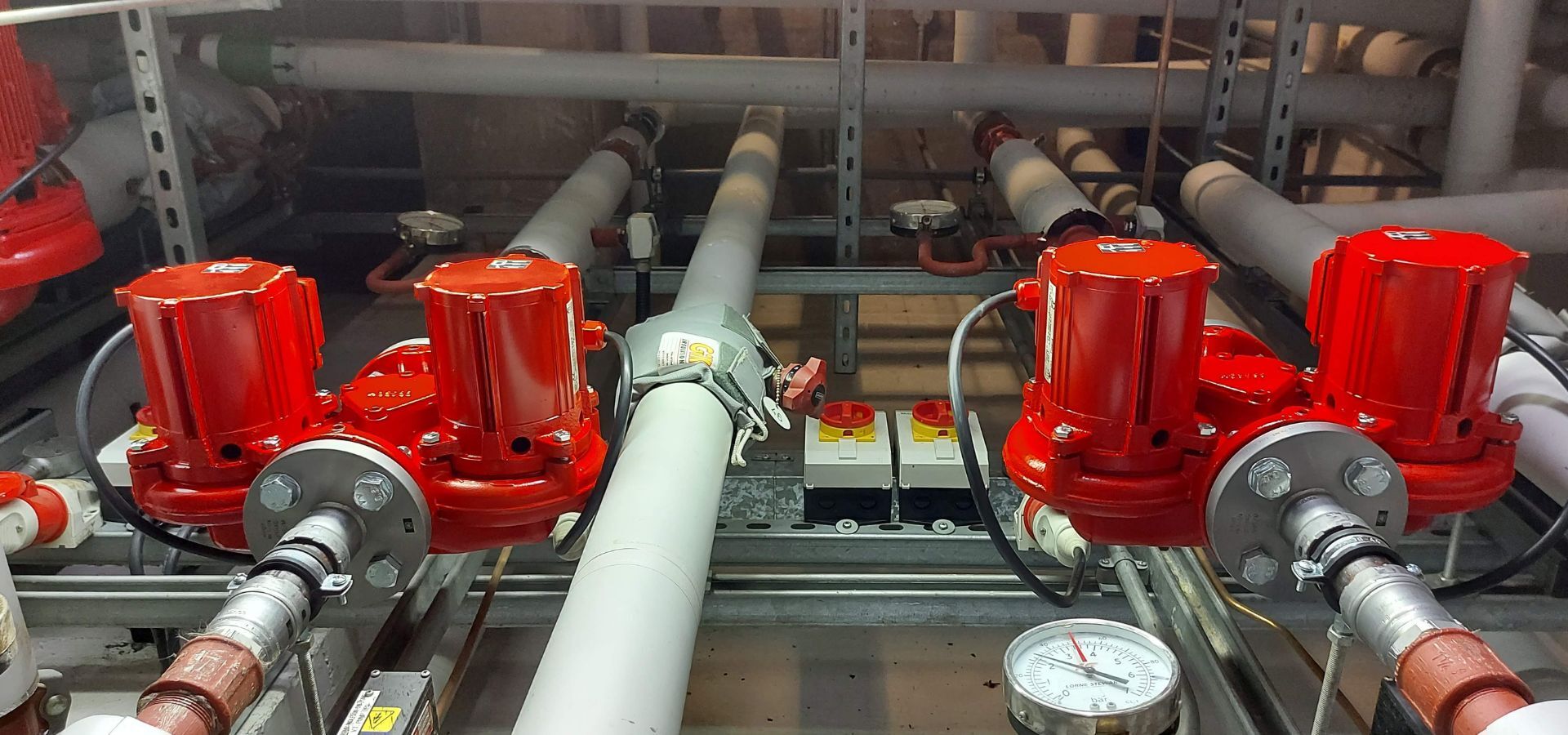

It might be time to upgrade, renew, or repair to a system that meets your needs. Downtime doesn’t need to be a barrier! We work around your schedules.

Here are five ways in which Dura Pump can support you.

Why Dura Pump?

Technical Excellence and Specialist Service Solutions:

- Custom Solutions for Your Challenges: Our expert team meticulously assesses your production environment to deliver pump systems tailored to your specific requirements.

- Reliability Through Innovative Design: We use cutting-edge technology to ensure your pumps operate at peak performance. This means that persistent issues are fixed and reliable and streamlined manufacturing processes are upheld.

- Energy Efficiency at our Core: Our pump systems prioritise energy efficiency. This will help to minimise your environmental impact and will also reduce operating costs.

- Seamless Scalability: Upgrading shouldn’t be a headache. We will ensure a smooth integration of your new system with minimal downtime. Our solutions are designed with scalability in mind.

- Precision Pump Selection: The key to a well-functioning system is the right pump for the right application. We only recommend pumps based on your specific needs.

Improve the Potential of Your Production Line!

Below are just some of our case studies where we delivered precision pump solutions to food manufacturing customers. If you are ready to transform your food manufacturing processes, please contact us today. We promise to deliver technical expertise, reliability, and energy efficiency.