A Grinder Pump is a centrifugal pump equipped with a grinder system at the pump inlet, which cuts larger particles and fibres into a homogeneous wastewater mass.

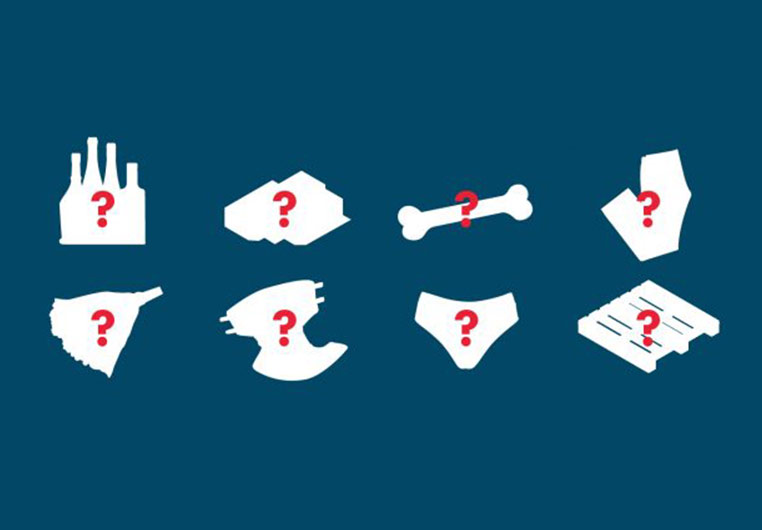

As a result, the risk of clogging in the pump and the pipe system is reduced to a minimum.

More importantly, a Grinder Pump is ideal for pump systems with smaller pipe diameters, where the flow is typically lower. This is relevant when pumping from remote areas or single houses. This pump type is not suited to pumping media with a high content of sand and they consist of more wearing parts, therefore requiring additional ongoing maintenance and spares.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800