The main purpose of a washdown systems set is to supply a comparatively high volume of water at a substantial pressure to washdown a process area. Typically washdown pump systems have hoses and gun configurations connected, to supply multiple uses and areas at any one time. The washdown pump system is identical to a booster set, however typically a lot higher pressure, and the units can be joined in series.

Low water pressure is becoming an increasingly worrying issue for many factories and industrial applications around the world. There are three main reasons for this:

- Increased hygiene standards

- A consistently growing demand for more water for washdown facilities

- A requirement for constant pressure as standard ensuring your process runs constantly

Washdown systems are the solution to low water pressure. By installing a washdown system, you achieve a constant reliable water pressure, giving your process the resource it requires.

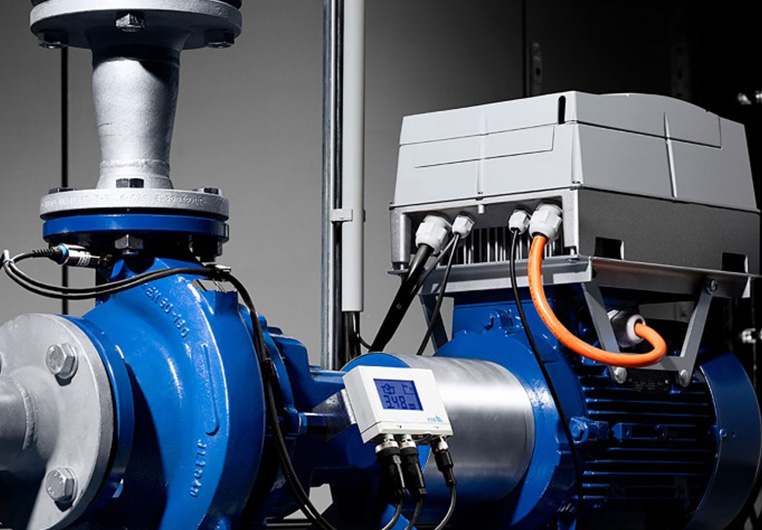

Old fixed speed washdown systems often are found to be running at full speed even when not in use. By replacing or upgrading these systems with variable speed drives there can be significant savings, providing excellent pay back times, and increasing your nett profit.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800