Centrifugal water pumps are used for many applications that Dura Pump can support. The common ones are:

Heating Circulation

Industrial centrifugal pumps in heating systems are used for circulating hot water around the building to maintain the distribution of the hot ( heating) water. They can vary from a main end suction shunt pump to a secondary inline canned/glandless pump. The inline pumps often found in heating systems are often twin twin-head pumps.

Cooling Circulation

Centrifugal water pumps in cooling or chiller systems are used for circulating chilled water around the building to cool the points that need it, for example operating theaters, server rooms and cool rooms/stores. They can vary from main long-coupled end-suction primary pumps to small glanded inline pumps

Clean Water

Centrifugal water pumps in a clean water system are typically used for boosting and moving the water from a break tank to the discharge point, for example, a tap or outlet . They are WRAS approved and typically have stainless steel construction. They are also used on HWS (hot water secondary systems), which mainly consist of bronze or stainless steel, circulating hot water around a loop via the cylinder to maintain heat.

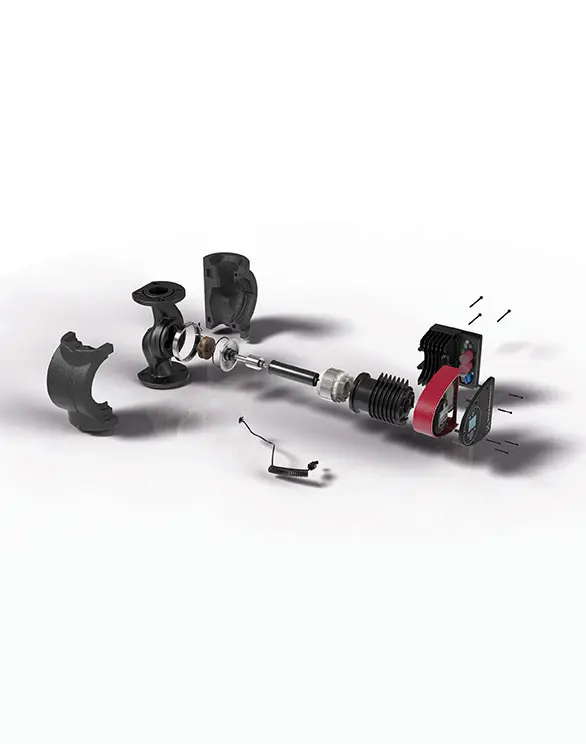

Industrial Centrifugal Pump

Centrifugal pumps in process plants are used for a wide range of liquids like water, chemicals and oils through various production stages. These can be fully stainless hygienic pumps or mag-driven chemical pumps, to waste water transfer pumps with open impellers. The correct material and specification are critical in these applications

Key product features/what we can offer

- Available in a wide variety of materials. The standard material is cast iron; however, stainless steel and duplex stainless steel are available.

- High temperature applications up to 350 degrees C

- Wide range of mechanical seal options to suit the application, including double mechanical seals and flushed mechanical seals.

- Standard range from 0.25 kW to 315 kW

- Pumps can range from 0 – 4800 m³/h and up to a maximum pressure of 40 bar with a single stage

- Repairs and replacements

- Fault finding

Common issues we can solve

Our Industrial Centrifugal Pump Manufacturers

Let’s Talk Pressure, we understand that every facility has unique demands. speak with a system expert today and get a recommendation built around your environment.