Save energy this summer: Are your systems running efficiently?

Posted on 10th May, 2019 by Dura Pump

Posted on 10th May, 2019 by Dura Pump

With summer just around the corner, it’s important to think about a few more key things than how you’re going to top up your tan.

We ensure our pumps keep the good times flowing for your leisure but with the sunny season fast approaching, heat can become detrimental to pumping systems that are faced with higher demand and pressure.

At Dura Pump, we strive to provide the best pump systems for our customers that make life easier. We care about solving every aspect of their needs, thereby ensuring a smoother process for their long-term pumping solutions. We also care about the world around us – which is why being considerate of the environment is an integral part of our ethos.

That’s why we operate a strict environmental policy and demonstrate not only responsible management in our business but want to help our customers reduce their dependence on energy. As summer approaches, we want to help our customers to understand how our pump systems can help them save energy from now on.

Why is an efficient pumping system important?

When it comes to the installation, maintenance and running of a pump system, there’s a key goal in mind: to make sure it works and does the job it was installed to do. However, there’s no reason for a pumping solution to be working in a way that consumes too much energy and therefore costs you more to maintain.

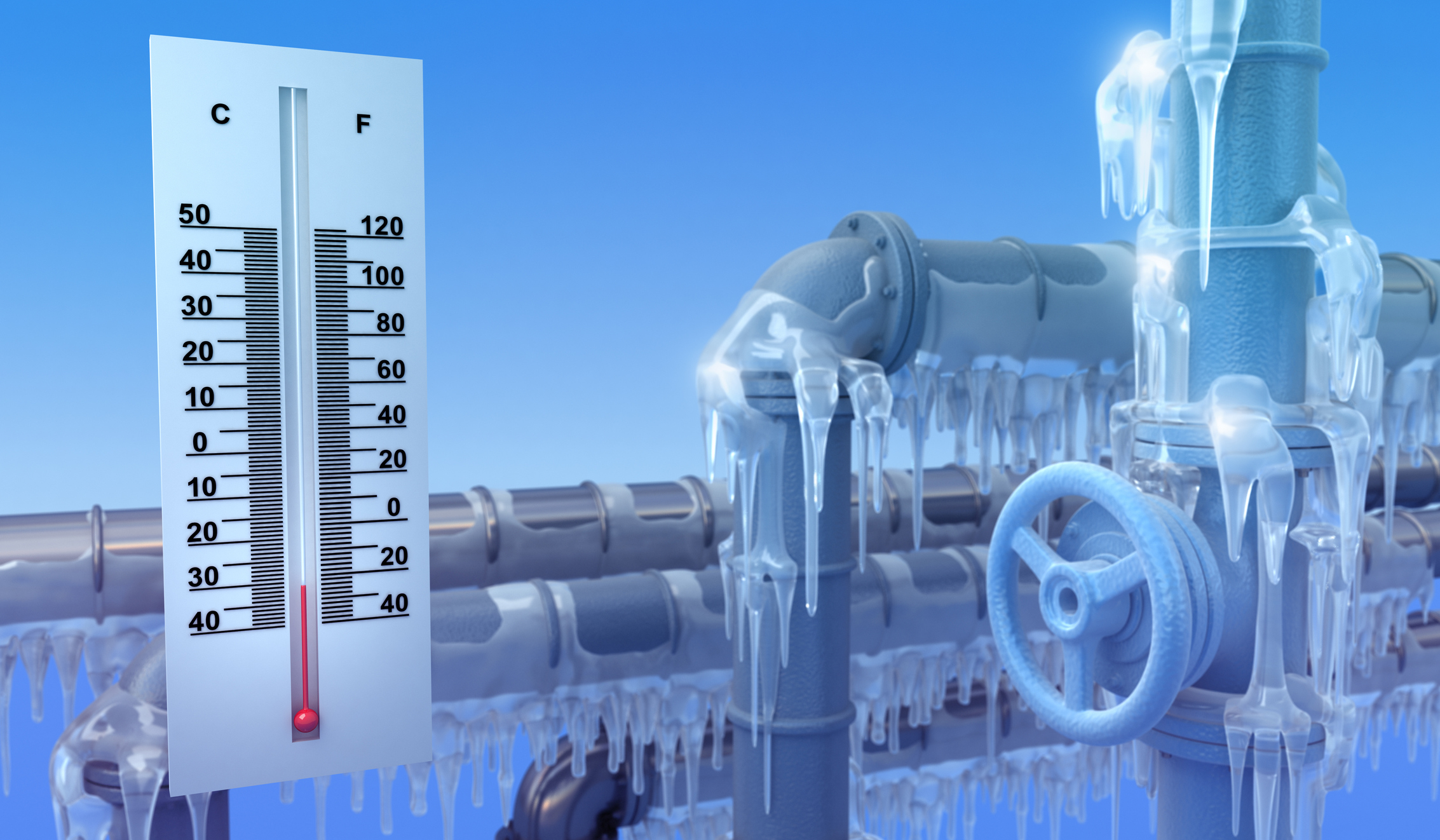

We’ve already covered energy wastage and its relation to heating systems but as summer rolls in, chiller systems become more of a requirement.

An efficient pumping system is important in order to ensure that you’re getting the most out of your pump choice and not slacking in areas where simple resolutions could be made. When it comes to energy savings, there are several ways that energy can become wasted.

Controlling your pumping system

Chiller pumps are running 24/7 but are often only required 50% of the time. Most pumps typically go unobserved year in and year out due to the fact they’re probably running okay. This leads people to turn a blind eye to the fact they use a lot of power whilst providing their services. However, pumps are often set up to accommodate worse case scenarios.

Chiller pumps will run constantly to ensure buildings and water supplies are kept cool but a lot of the time this isn’t a necessity – meaning the pump is running more than it needs to. So you might wonder how to know when the system needs to be work at high efficiency?

Our engineers can conduct a thorough system analysis to identify system usage. By analysing this data, we are able to make necessary modifications such as output alteration. We can make your system run at 50% which equates to 25% of total power consumption. What people don’t realise is that basic pump control can be used to save around 40% of the energy used. This is huge!

We’ll also review how the pumps are controlled which could lead to further savings. For example, if we can analyse chiller pumps are not required at night we’ll figure out a lower percentage for their running or turn them off altogether.

A new pump for the summer?

Pump control is not the only reason why you could be losing money and wasting energy. Issues with the pump, whether in the initial installment stages or in the later processes, can incur damaging wastage and lack of efficiency.

Small margins of error during installation can lead to systems being put under 45% more pressure than necessary. That’s why when Dura Pump installs its pumps, our engineers meticulously evaluate what is really being used on site through system requirement analysis. We remove the guesswork so we don’t need margins. This accurate system analysis means that an exact duty pump can be selected. We can even customise a pump to suit exact requirements that maximise efficiency every time.

So if your system is going into the summer with years of experience on its shoulders, this might not be a good thing. Aging is always going to be an issue and everything depreciates with time. A pump that is over a decade old will not be incorporated or fitted using contemporary technology which already means they are running to a lower standard than current pumping solutions.

By using Dura Pump, we can ensure a high quality system is installed with all the right data behind it to help

your system be energy efficient and powerful.

Systems for savings

Our pumping solutions are fitted with your needs and energy saving in mind. That’s why our chiller and pump systems will ensure you’re saving energy this summer and for years to come.

Statistically, pumps account for 10% of the world’s energy consumption but are wasting energy 95% of the time. With your organisation relying on a pumping system to meet its needs, the correct pump will be pivotal.

A correctly installed and maintained chiller pump can help increase your energy savings in no time at all. Dura Pump pumping solutions have helped cut costs all across the industries, in places such as:

- Retail Shopping Parks – On-going maintenance costs reduced by £120,000

- Storage and Distribution – 50% power savings

- Food Manufacturing – 73% reduction in power used

- Hotels – Over 95% savings on pump blockages

- Heat treatment company saved £31,000 per year

- Leisure Centre saved £8,500 per year

An injection moulding company had experienced consistent failures over two years from its eight x 18.5 kW chiller pumps feeding chiller units. We made an initial site visit to collect data and then brought that back to our headquarters.

As a result, we fed the data through our flow analysis software, which gave us the necessary pressures, friction loss, flow rate and load information we needed to design a solution. We also analysed the existing pump performance curves to get an understanding of all the current flow rates and pressures. We specified, sourced and supplied eight new 15 kW centrifugal pumps, and installed them without turning the system off, which saved downtime.

Once we had finished the work, the failures had been completely eliminated. As the trusted supplier to the injection moulding company, we have been in regular contact with them to help maintain and service their equipment. They had achieved payback within six months.

Over the last five years, they have saved 500,000 kWh per year, which is £50,000 per year in power alone, and £250,000 over the five years. In addition, they have had zero pump failures, which has saved them significant amounts of downtime.

Where to find pumping solutions?

At Dura Pump, we offer an expensive range of chiller pumps, whether you are creating a new system or need to replace a failed chiller pump. We are particularly diligent at sourcing obsolete chiller pumps, and we are great at supplying the best direct substitute if the one you need is no longer available.

If you need to save energy this summer and for years to come, then Dura Pump can reduce your energy wastage in no time. With our free site survey option and flow analysis software, we have all the tools and know-how at our fingertips to ensure you have the correct pump working in the right way.

Summer will here be here before we know it so don’t hesitate to find out more or get in touch on 01604 648 800 or mail@durapump.co.uk to discover how we can help you.