Dura Pump offers energy saving pumps, which can save hundreds of thousands of pounds in running costs, reduce your carbon footprint and optimise your system.

We can save between 30% to 65% on most pump systems while ensuring consistency of delivery to your facility.

Book your energy saving audit

Energy saving audit & review

Energy saving audit & review

Our energy saving audit starts with a no-obligation site survey. Our experienced pump consultant will carry out a detailed assessment of your pump station and pump systems, the energy system in place and the amount of time and money that is currently being expended on the system.

Specification & proposal

Specification & proposal

After the initial survey, we carry out an in-depth assessment of your system using our flow profile analysis tool and energy calculations. This gives us the necessary pressure, friction loss, flow rates and load information we need to match system energy and efficiency on real-time loads. This allows us to establish if your system is already cost-efficient and if there are specific areas to recommend upgrades to optimise your system to match real-time loads or to identify usage data in the field or efficiency that reduces wear and tear on the pump. As part of this diagnosis, we identify the most energy-efficient solution for your system and provide a quotation to supply and install both detailed energy-saving calculations and the payback on your investment.

Installation & commission

Installation & commission

Following your acceptance of the quotation, we will manufacture, supply, install and optimise the energy pumps solution. We install in a way that ensures all equipment works to its optimum performance. We work to minimise your downtime during the installation because we know how important continuity is to all organisations. Our team will provide you with a caring and friendly service.

Payback & ongoing savings

Payback & ongoing savings

Preventative maintenance and care keeps your system at full performance and we offer a range of Proserv maintenance packages to give you complete peace of mind and ensure your system remains reliable, energy-efficient and continues to deliver ongoing savings to you.

Facts About Energy Saving Pumps

With the current need to reduce energy consumption and the big drive to save the planet, we’d like to inform you how Dura Pump is doing our bit.

Our energy savings audits inform customers on how we can save them money and energy on their pumps and pump systems.

You may be thinking that this isn’t possible, however we are confident that if there is a saving to be had, we will find it.

Having been in the pump industry for many years, we know how to optimise pumps for energy savings and address the technical nature of the energy savings issue.

This NHS example demonstrates how systems can be optimised to save both energy and running costs

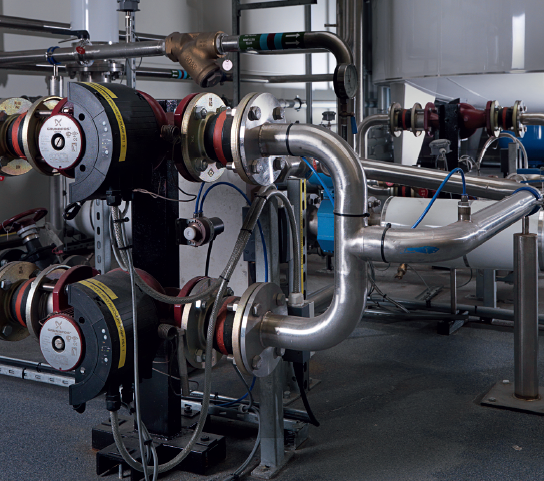

- The hospital had two 37kW belt driven pumps. One pump was running 24/7, alternating duty unless extra flow was needed, and they would both run together.

- The energy these pumps used totalled 291,708 kWh of electricity per year.

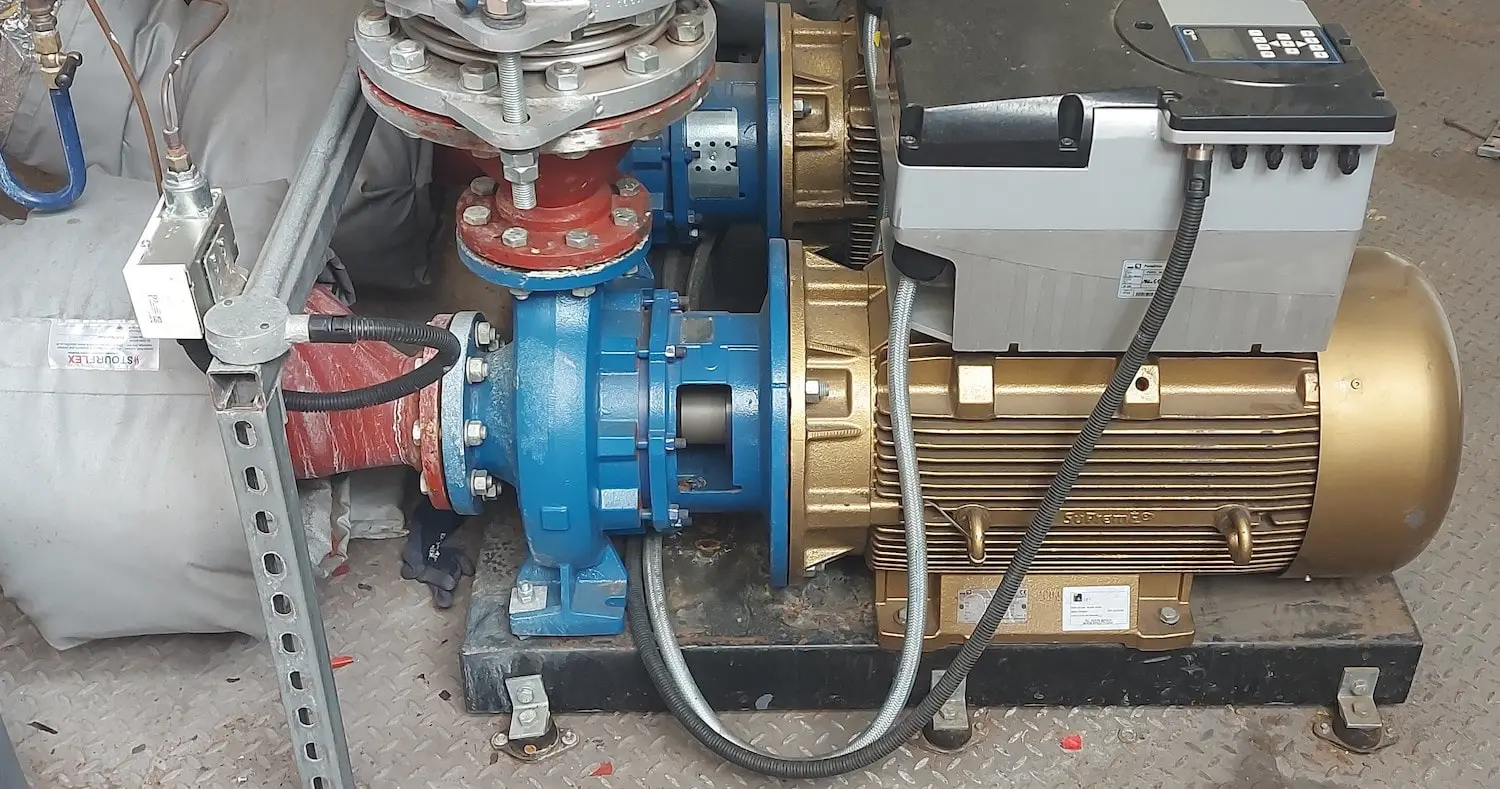

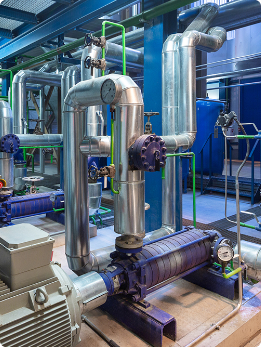

- After assessing the system, we specified two direct drive pumps to replace the existing belt drive pumps. The variable speed of these new pumps is controlled by an inverter and linked to them is a sensor which monitors the return temperature of the water regulating the speed of the pumps and the return temperature.

- The new pumps specified were 18.5 kW with an estimated energy saving of 40% from the inverters. This reduced the kWh used per year from 291,708 kWh to 97,216 kWh, saving 194,472 kWh of electricity. All this by simply changing the pumps and adding inverters.

Before

After

- Total job cost for the hospital = £35,000.

- Cost saving per year = £48,603 (194,412 kWh x 0.25p per kWh), meaning that the job paid for itself within 9 months.

- This hospital saw an ROI in under a year. In five years, the customer will have saved over £240,000.

- From a sustainability point of view, the CO2 savings on this job = 45,297.99 kg of CO2 (0.233 kg of CO2 per kWh x 194,412 kWh), meaning that this project saved 45 tonnes of CO2 from entering the atmosphere each year.

*Calculations based on averages

Pump Energy Savings Summary

Job Cost: £35,000

£ Savings P/A: £48,603

Energy Savings: 194,412 kWh

C02 Savings: 45,297.99 kg

ROI: 9 months

Identify your pump energy savings

Could you improve?

- The lifespan of your pump

- It’s operating efficiency

- It’s accuracy in operating

- It’s speed of return.

If you answer “yes” to any of these questions, we can help you make significant energy savings.

Contact us for a site survey or try out our

Energy savings calculator Book your energy audit

Identify your savings

Alternatively, if your pumps look like any of these two pictures, we can definitely deliver energy savings to you.

Book your energy audit

Pump Energy Savings FAQs

You can save more than 60% on power use by changing. Contact us to find out how.

If the motor is 2.2kW+, savings of 17-75% are often seen by simply adding an inverter. Contact us to find out how.

If your system has a drop of pressure at peak use, you may benefit from switching to a variable speed system. Contact us to find out more.

If you have a 0.55kW+ heating pump, it may be eligible for inverter control. Contact us for further information.

Inverter control can improve the efficiency and flexibility of your motors, especially in variable-load applications. Contact us to find out how.

Outdated controls can lead to inefficiencies. Upgrading offers the chance to optimise energy use. Contact us to find out how.

Process cooling pumps often run at full speed unnecessarily. Significant energy can be saved using control systems. Contact us to find out how.

Your pumps may be oversized or inefficient for the new demand profile. Savings opportunities exist. Contact us to find out how.

Upgrading the logic or control algorithm can greatly improve efficiency and responsiveness. Contact us to find out how.

Running pumps during non-operational hours often leads to wasted energy. Contact us to discuss further.

Related Case Studies

Modernising Hospital Clean-Water Pumps: Shrinking the NHS Maintenance Backlog with Smarter Assets

Read moreComplete Pump Overhaul for Modular Correction Facility

Read moreYour Essential Guide to Winter-Proofing Pumps

Read moreEmergency Booster Set Repair at a High-Security Prison

Read moreBoosting Critical Cold Water for NHS Trust Patients

Read moreRapid Response & Energy Savings for NHS Hospital Pump System

Read moreHospital Saves 40% on Energy Costs

Read moreStay Ahead of Pump Problems with a Proserv Maintenance Package

Read moreMaximising Efficiency with a Dura Pump Maintenance Package

Read moreMaximum Energy Efficiency Delivered for London Landmark

Read moreMajor London Railway and Underground Station Chooses Dura Pump for Booster Set Upgrade.

Read moreWould you like to see a 60% saving on your electricity?

Read moreSlaughter and May Case Study

Read moreInline Centrifugal Pump Replacement For College

Read moreDura Pump solution pays back in 10 months for leading food supplier

Read moreChoosing Dura Pump means investing in reliability and safety for your facility. Talk to an expert about your needs